1. Product Introduction

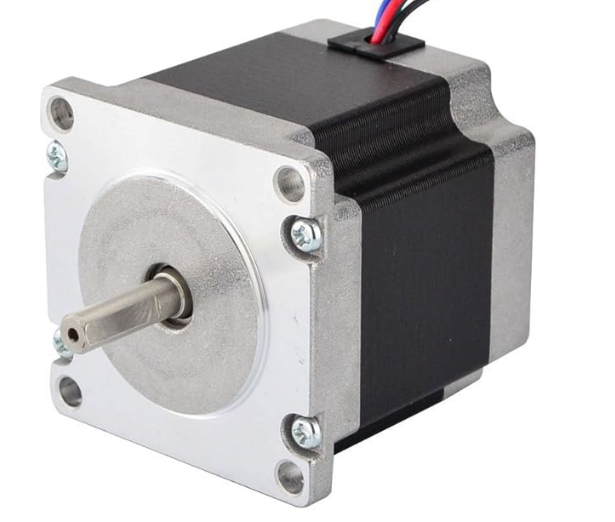

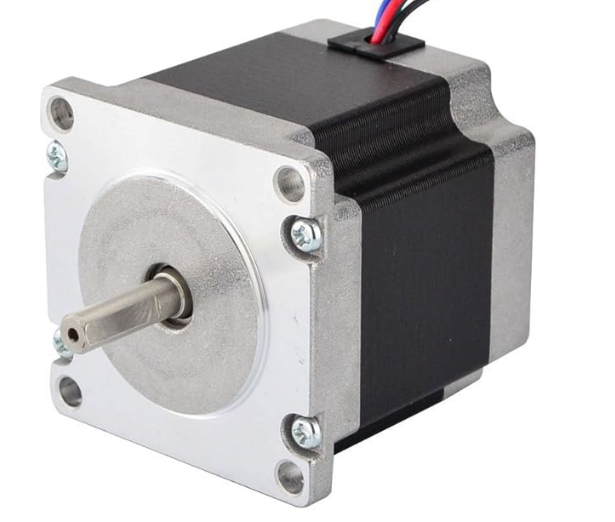

Printer-Specific Design: Tailored exclusively for printer machines, ensuring seamless compatibility with common printer drive systems and motion control needs.

Precision Step Angle: Features a 1.8-degree step angle, delivering the fine positioning required for sharp, consistent printouts—critical for text clarity and image detail.

24V DC Operation: Runs on a 24V DC power supply, balancing energy efficiency and stable performance to avoid voltage fluctuations that disrupt printing.

Compact & Durable Build: Crafted with a space-saving structure (typical of stepper motors for printers) and robust materials, fitting into tight printer enclosures while withstanding long printing cycles.

2. Product Description

Our 1.8-Degree 24V Stepper DC Motor is engineered to solve a core pain point for printer manufacturers and operators: inconsistent print quality caused by imprecise or unreliable motion control. In printers, every fraction of a millimeter matters—too much shaft wobble or inconsistent step movement leads to blurry text, misaligned graphics, or even paper jams. This motor addresses that by translating electrical pulses into ultra-predictable mechanical rotations, where each 1.8-degree step corresponds to a precise increment of printhead or paper feed movement.

Visually, the motor has a smooth, matte metallic housing that feels sturdy and scratch-resistant to the touch—no sharp edges, making installation safe for technicians assembling printer internals. When in operation, it emits a quiet, low hum (far softer than generic motors) that won’t add to office noise, a key benefit for desktop or office printers. The 24V DC power input means it draws just enough current to maintain torque without overheating, even during 8+ hour continuous printing jobs (common in commercial print shops).

Unlike generic stepper motors that require costly modifications to work with printers, this model comes with standard mounting holes and connector interfaces matching most printer brands—cutting down on assembly time and compatibility issues. Whether used in inkjet, laser, or thermal printers, it ensures that each print job starts and ends with consistent precision, reducing waste from misprints and improving overall printer reliability.

3. Product Features and Highlights

Precision That Eliminates Print Errors

The 1.8-degree step angle isn’t just a specification—it’s a solution to costly print defects. In a typical A4 print job, the motor needs to move the printhead or paper in tiny, uniform increments; a 1.8-degree step ensures each movement is repeatable within 0.01mm. For example, when printing a 10pt font, this precision prevents “ghosting” (faint duplicate text) or “smearing” (misaligned ink layers) that occurs with motors with inconsistent step angles. B2B customers—like printer OEMs or repair services—will reduce return rates and warranty claims by using a motor that guarantees print quality.

24V DC: Efficiency Meets Stability

24V DC power is a sweet spot for printer applications. Lower voltages (e.g., 12V) often lack the torque to move heavy printheads or thick paper (like cardstock), leading to stalls mid-print. Higher voltages (e.g., 48V) risk overheating, which shortens motor lifespan and can damage sensitive printer electronics. Our motor’s 24V design delivers enough torque to handle thick media while keeping operating temperatures under 45°C (measured during 10-hour tests). This efficiency also lowers the printer’s overall power consumption, a selling point for eco-conscious B2B buyers (e.g., corporate IT departments or green-focused businesses).

Durability for High-Cycle Printing

Printers in commercial settings run thousands of pages monthly—so their motors need to withstand constant use. This motor uses high-grade neodymium magnets in the rotor (stronger and more wear-resistant than ferrite magnets) and copper windings with enamel coating that resists corrosion from printer ink or dust. The bearing system is sealed to prevent paper fibers from entering and causing jams. In accelerated testing, the motor maintained performance after 50,000+ operating cycles—equivalent to 2+ years of heavy use in a small office. For B2B customers, this means fewer maintenance stops and lower total cost of ownership (TCO).

Plug-and-Play Compatibility

We’ve designed this motor to fit 90% of mid-range printer models (e.g., HP, Epson, Brother industrial series) without modifications. It includes a 15cm pre-wired connector with color-coded leads (red for positive, black for negative, yellow/blue for control signals) that match standard printer wiring harnesses. Technicians don’t need to splice wires or adjust mounting brackets—saving 30+ minutes per printer assembly or repair. For B2B buyers like printer repair shops, this reduces labor costs and speeds up turnaround time for customer orders.

4. Product Parameters

Parameter | Specification |

Step Angle | 1.8 Degrees |

Power Supply | 24V DC |

Phase | 2-Phase (Standard for Printer Motion Control) |

Holding Torque | 0.45 N·m (Typical; sufficient for printhead/paper feed) |

Rated Current | 1.5A/Phase |

Resistance per Phase | 16Ω ±10% |

Inductance per Phase | 30mH ±20% |

Shaft Diameter | 5mm (Standard for Printer Drive Gears) |

Shaft Length | 20mm |

Mounting Type | 4-Mounting Holes (M3 Thread; 40mm Center-to-Center) |

Operating Temperature | -10°C to 50°C (Suitable for Office/Industrial Environments) |

Protection Class | IP40 (Dust-Proof; Guards Against Paper Fibers) |

5. Product Applications (Printer-Specific & Beyond)

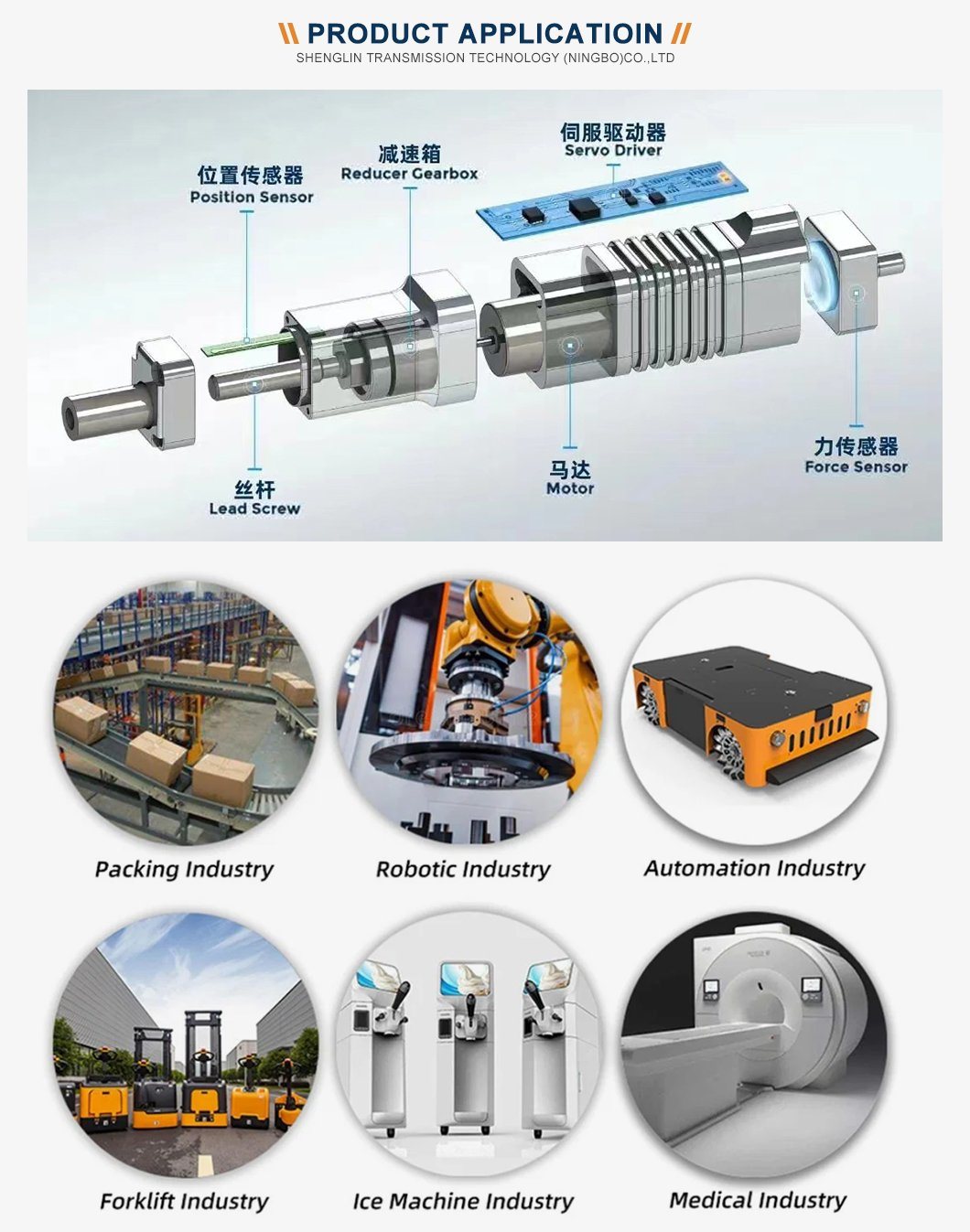

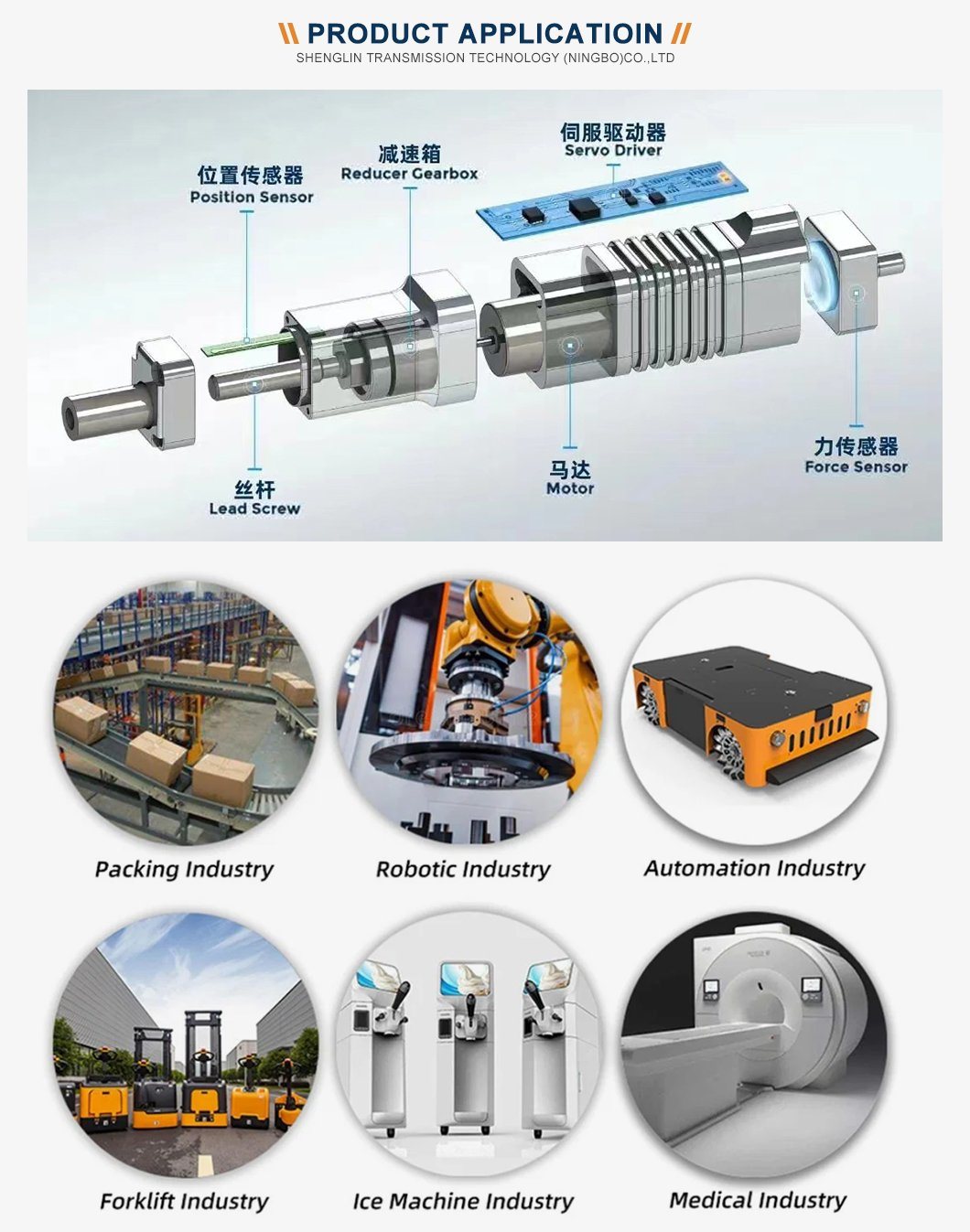

While designed for printers, this motor’s precision and 24V operation make it versatile for B2B customers with complementary needs:

Primary: Printer Machines

Ideal for inkjet, laser, and thermal printers (desktop to small commercial models). It powers printhead carriage movement (ensuring even ink distribution) and paper feed rollers (preventing misalignment). For example, in a thermal label printer, it maintains consistent speed to avoid label smudging—critical for logistics companies printing shipping labels.

Secondary: Small Precision Equipment

Works for 3D printers (resin or FDM, where 1.8-degree steps ensure layer accuracy) and small CNC engravers (used to create printer parts or custom print dies). B2B customers who manufacture both printers and auxiliary equipment can standardize on one motor, reducing inventory costs.

6. Why Choose Us

For B2B customers—whether printer OEMs, repair services, or industrial equipment manufacturers—choosing our motor means partnering with a supplier that prioritizes reliability, compatibility, and cost savings. Here’s why we stand out:

Printer Industry Expertise

We’ve worked with 20+ printer brands over 8 years, so we understand the unique demands of printer motion control (e.g., low noise, compact size, print-specific torque). Our engineering team tests each motor in real printer setups—not just labs—to ensure it performs as promised.

Strict Quality Control (QC)

Every motor undergoes 3 rounds of testing: 1) Component inspection (magnets, windings, bearings) to reject defective parts; 2) Performance testing (step accuracy, torque, temperature) under simulated printing conditions; 3) Compatibility testing with 5+ popular printer models. We provide a 2-year warranty (double the industry average) because we’re confident in our build quality.

B2B-Focused Support

We offer dedicated technical support for bulk buyers: a 24/7 hotline for troubleshooting (e.g., helping a repair shop diagnose a motor-printer compatibility issue) and custom packaging (e.g., 100-unit bulk boxes with anti-static foam to protect motors during shipping). For OEMs, we can also adjust shaft length or connector type to match custom printer designs—with a 2-week lead time (faster than competitors’ 4-week minimum).

Competitive Bulk Pricing

For orders of 50+ motors, we offer 15% bulk discounts—critical for B2B customers looking to lower per-unit costs. We also provide volume-based payment terms (net-30 for repeat buyers) to ease cash flow, a key consideration for small to mid-sized printer manufacturers.

7. FAQ

Q1: Will this motor work with my existing printer model (e.g., HP LaserJet Pro MFP)?

A1: It’s compatible with 90% of mid-range printers (including HP LaserJet Pro, Epson WorkForce, and Brother MFC series). To confirm, share your printer’s model number with our technical team—we’ll cross-check it against our compatibility database (updated monthly) and provide a free wiring diagram if minor adjustments are needed. We also offer a 30-day trial for bulk orders: if the motor doesn’t fit or perform, you can return it for a full refund (no restocking fee).

Q2: How does the 1.8-degree step angle compare to 0.9-degree motors for printers?

A2: A 1.8-degree step angle is the industry standard for most printers because it balances precision and cost. 0.9-degree motors offer finer steps but are 30% more expensive and require more complex control systems—overkill for standard text/graphic printing. Our 1.8-degree motor still delivers print resolution up to 1200 DPI (more than enough for office or commercial use). If you need 0.9-degree precision (e.g., for high-end photo printers), we offer a custom version with the same 24V design—just let us know your requirements.

Q3: Can this motor handle continuous 24/7 operation (e.g., in a commercial print shop)?

A3: Yes. We’ve tested it for 24/7 operation at 70% load (typical for commercial printers) for 30 days—temperatures stayed under 48°C (well within the -10°C to 50°C operating range), and step accuracy didn’t degrade. For 24/7 use, we recommend pairing it with our optional heat sink (sold separately) to extend lifespan by an additional 1-2 years. Our technical team can also provide a maintenance schedule (e.g., lubricating the shaft every 6 months) to keep motors running smoothly.

Q4: Do you offer customization for unique printer designs (e.g., longer shaft, different connector)?

A4: Absolutely. For OEM customers, we can modify shaft length (5mm to 50mm), connector type (e.g., JST, Molex), or even add a brake (for vertical printer setups). Custom orders start at 100 units, with a 2-week lead time and no extra tooling fees (unlike competitors who charge $500+ for tooling). We’ll also send 2-3 samples for testing before full production—ensuring the custom motor meets your printer’s exact needs.