Product Overview

Core Design & Application

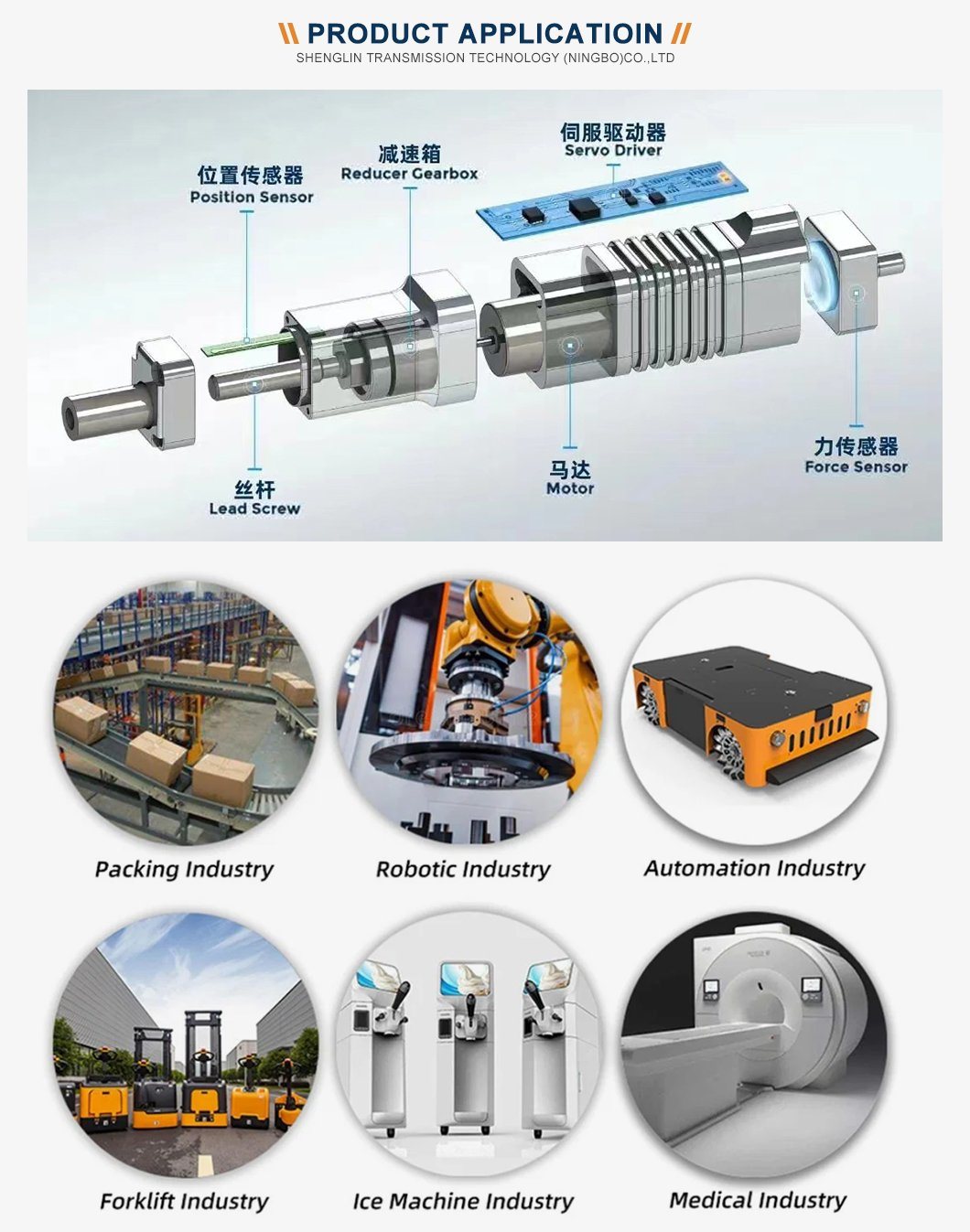

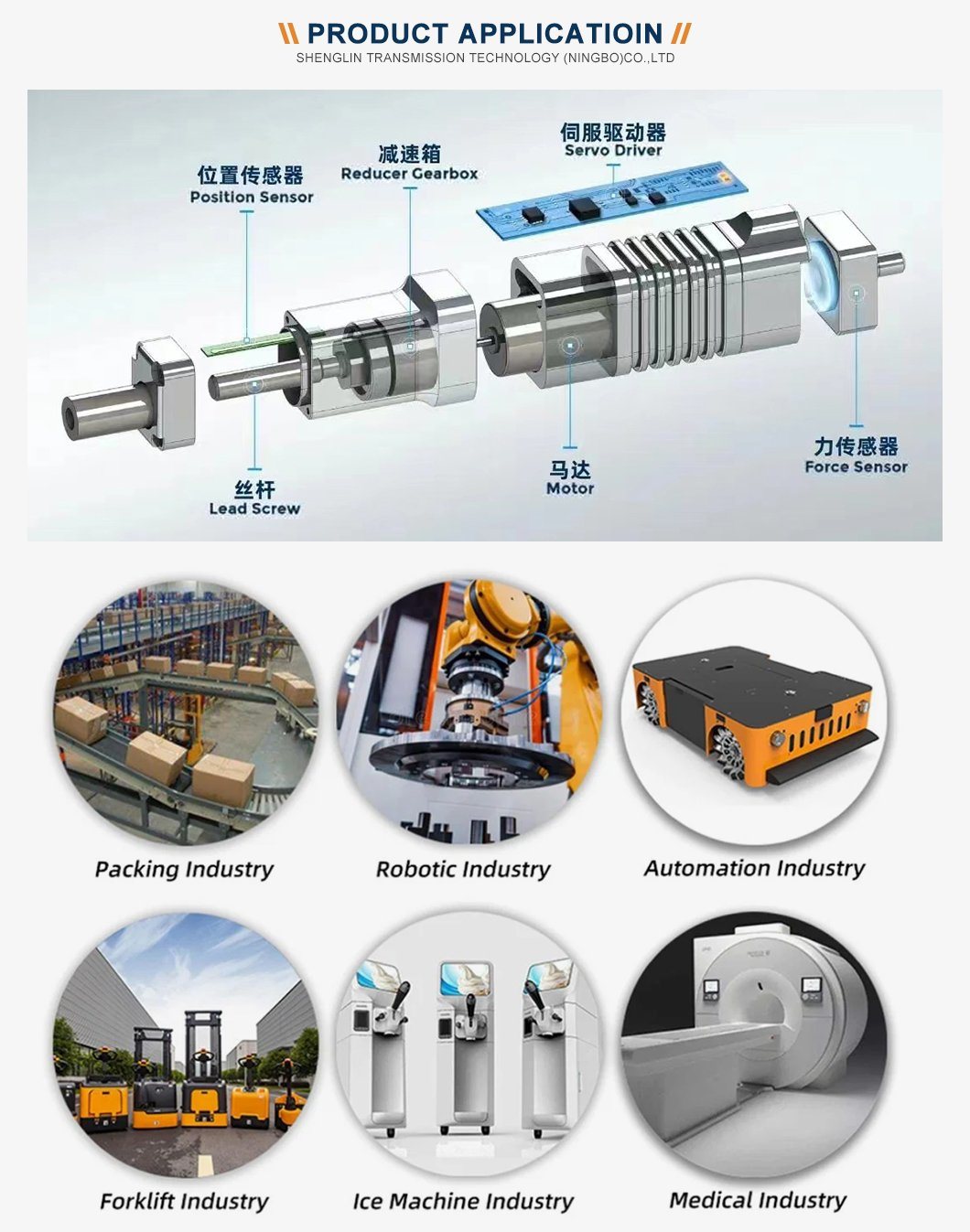

This planetary DC brushless (BLDC) motor is available in 60W, 80W, and 100W power options, integrated with a high-precision planetary gearbox. It is engineered for high performance in robotics, industrial automation, packaging machinery, and medical equipment—scenarios that demand high torque, low noise, and precise motion control. Unlike traditional brushed motors, its brushless design reduces maintenance needs and extends service life.

Key Product Advantages

It combines the compact size of planetary gearboxes with the efficiency of BLDC technology, making it suitable for space-constrained applications while delivering stable power output. It also supports customization to fit specific functional requirements of intelligent equipment.

Product Advantages

• High Torque & Compact Size: The planetary gearbox design amplifies torque output without increasing the motor’s overall size, making it ideal for small robotics and compact automation systems.

• Low Noise Operation: The brushless structure and precision gear meshing minimize acoustic emission, ensuring quiet operation in noise-sensitive environments like medical facilities and office automation equipment.

• Superior Efficiency & Long Lifespan: Brushless technology eliminates brush wear, reducing energy loss and maintenance frequency. It maintains high efficiency even during long-term continuous operation.

• Precise Motion Control: It provides smooth and accurate speed and position control, meeting the strict precision requirements of robotic arms, conveyor systems, and medical devices.

• Strong Durability: Built to withstand rigorous industrial use, it resists wear and tear, ensuring consistent performance in harsh operating conditions.

Technical Specifications

Basic Power & Structure Parameters

• Power Range: 60W, 80W, and 100W, covering medium-power application needs from light-duty automation to small robotic drives.

• Motor Type: DC brushless (BLDC) with a planetary gearbox, ensuring efficient power transmission and torque amplification.

• Operating Characteristics: No brush friction, low electromagnetic interference, and stable speed output—suitable for both continuous and intermittent operation.

Performance Metrics

• Torque Output: Optimized by the planetary gearbox, it delivers exceptional torque relative to its size, meeting the load requirements of robotic joints, packaging machine conveyors, and medical device actuators.

• Speed Control: Supports precise speed adjustment, with smooth acceleration and deceleration to avoid motion shocks in sensitive applications.

• Environmental Adaptability: Designed for industrial environments, it operates stably in normal temperature and humidity ranges (compatible with most factory and medical facility conditions).

Customization Options

• Mechanical Customization: Adjustments to the gearbox reduction ratio, output shaft size, and mounting dimensions to fit specific equipment installation requirements.

• Electrical Customization: Modifications to voltage (compatible with common industrial DC voltages) and control signals to integrate with different automation control systems.

• Lead Wire Customization: Changes to lead wire length, model, and connector type to match on-site wiring needs.

Why Choose Us

• Comprehensive Product Line: Beyond planetary BLDC motors, we produce micro AC gear motors, permanent magnet brushed DC motors, stepper motors, servo motors, and high-precision planetary reducers. This allows us to provide one-stop transmission solutions for your automation projects.

• R&D Capabilities: Our team focuses on the automation industry and intelligent equipment field, with multiple product technical indicators reaching international standards. We can develop customized solutions for complex application scenarios.

• Proven Reliability: Our motors are exported globally, with a track record of stable performance in robotics, automation, and medical industries—backed by years of market verification.

• Customer-Centric Service: We provide detailed product recommendations based on your application scenarios, guide sample testing, and ensure smooth communication throughout the order and after-sales process.

FAQ

Q1: What industries is this planetary BLDC motor suitable for?

A1: It is ideal for robotics, industrial automation, packaging machinery, medical equipment, and other fields that require high torque, low noise, and precise motion control.

Q2: Are you a factory or a trading company?

A2: We are an industry-trade integrated company in Ningbo City, Zhejiang Province, with our own manufacturing plants and R&D teams.

Q3: How to start a customization order for the motor?

A3: First, make an inquiry and inform us of your application scenario (e.g., robotic arm, packaging machine), required power (60W/80W/100W), and any special requirements (e.g., reduction ratio, mounting size). We will then provide design recommendations, customize drawings and samples, and proceed with mass production after sample confirmation.

Q4: What transportation methods are available?

A4: We offer express, sea, air, and other transportation methods. You can choose the most suitable one based on your delivery time and cost requirements.