Product Overview

The Solid Quality NEMA34 Hybrid Stepper Motor is a high-precision drive component that converts electrical pulse signals into precise angular displacement or linear displacement. As a leading hybrid stepper motor, it combines the advantages of permanent magnet and variable reluctance stepper motors, delivering exceptional positioning accuracy, smooth operation, and reliable performance. The NEMA34 stepper motor is engineered for applications that demand precise motion control, from 3D printers and laser engravers to medical equipment and industrial automation systems. Its robust construction, high holding torque, and low noise operation make it a preferred choice for engineers and manufacturers seeking consistent, high-quality drive solutions.

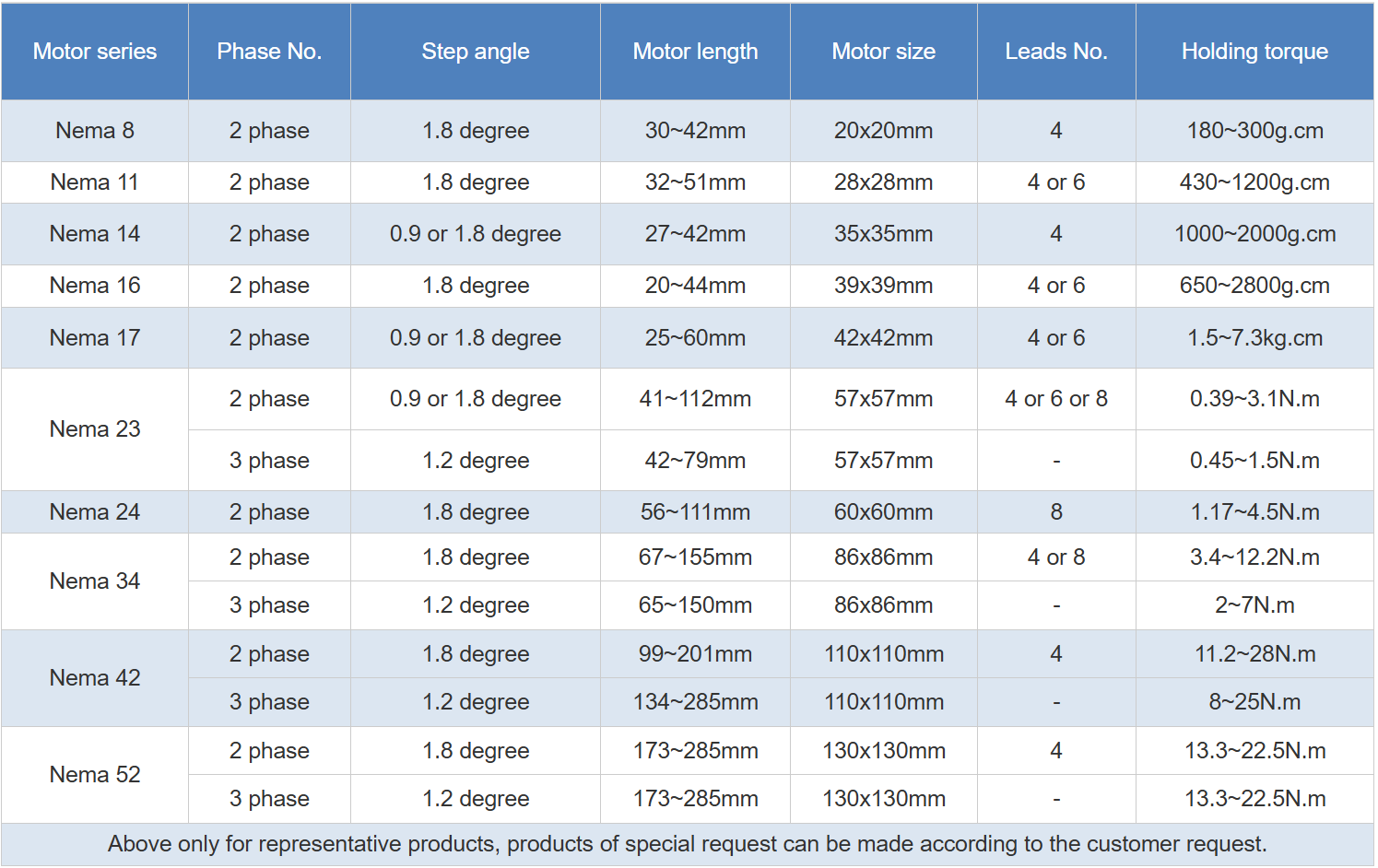

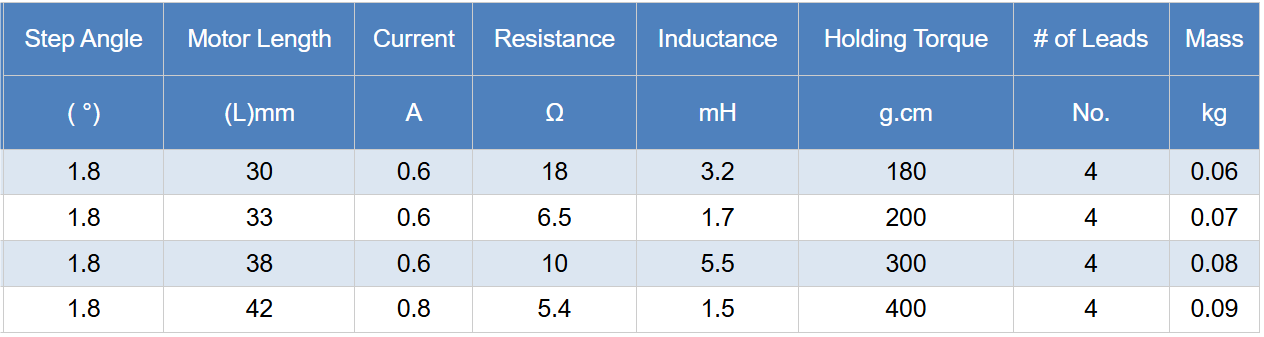

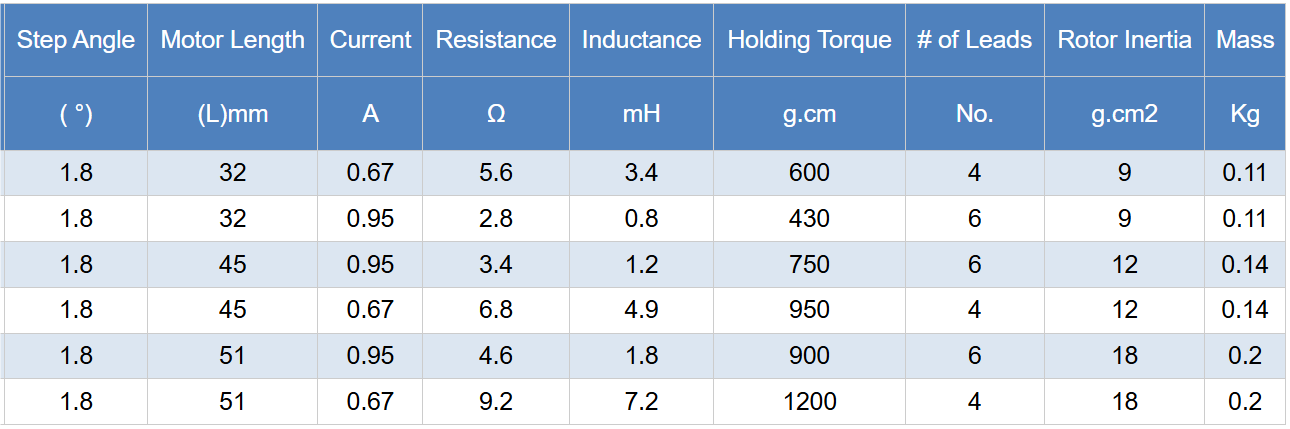

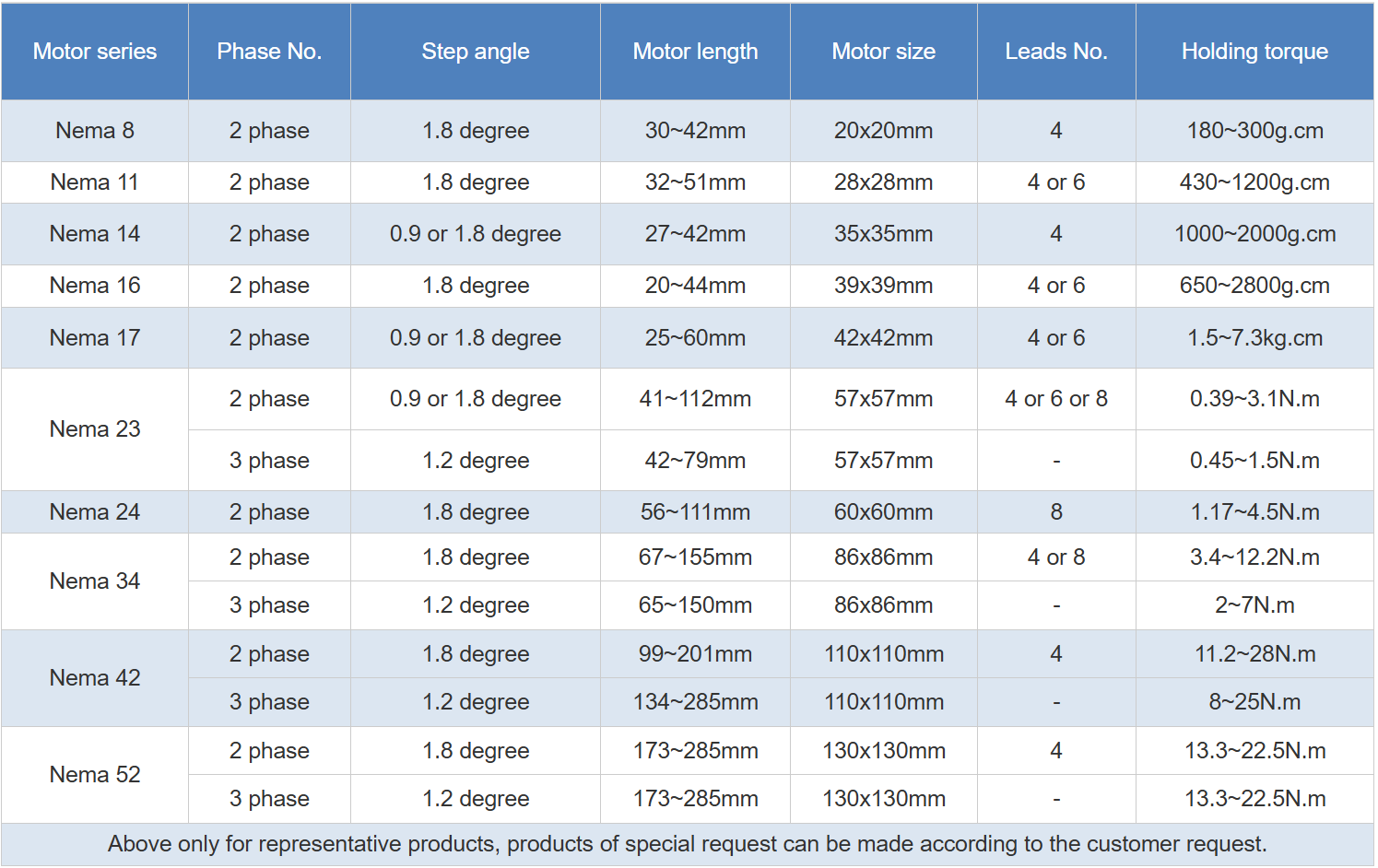

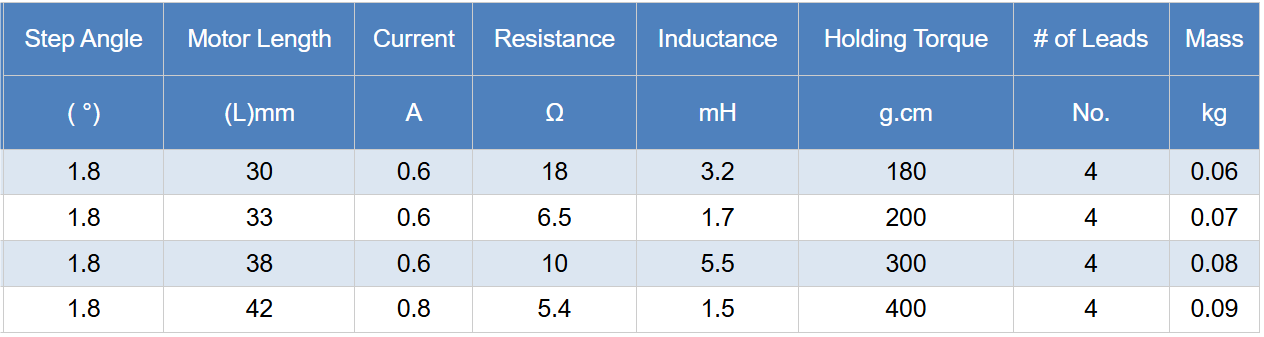

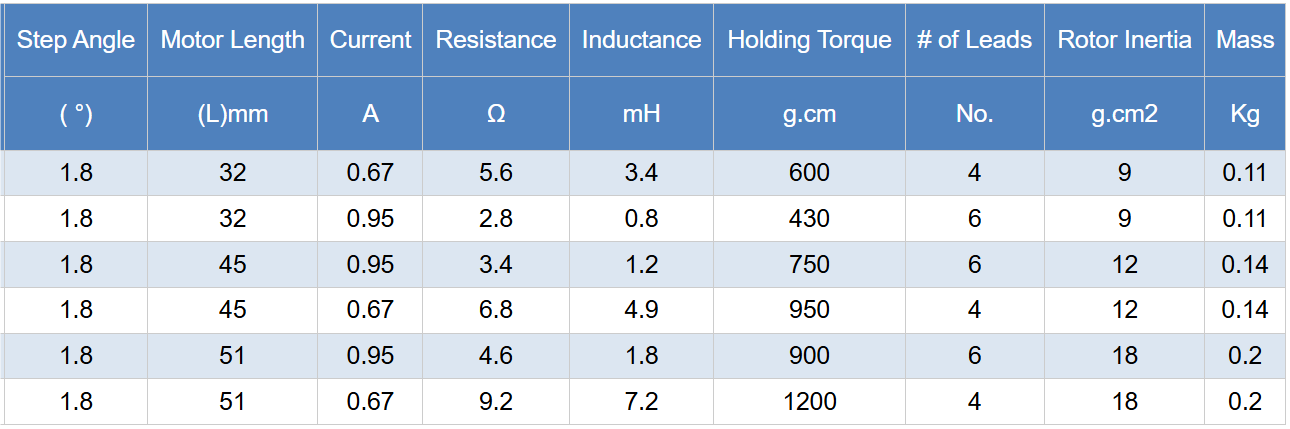

Technical Parameters

Core Component Configuration

The motor features high-grade SH-level magnetic steel, which enhances magnetic performance and holding torque. The coated rotor is precision-machined to reduce burrs, ensuring smooth rotation and minimal noise. The stator and rotor undergo rigorous individual testing before assembly to guarantee compatibility and performance. The motor is available in multiple phase configurations, with a step angle designed for precise positioning, and various lead options to accommodate different control systems.

Design Specifications

The NEMA34 hybrid stepper motor boasts a compact, rugged design with a motor size optimized for balance between power and installation flexibility. Its insulation grade meets industrial standards, ensuring safe operation in various environmental conditions. The motor’s windings are designed for efficient energy conversion, reducing heat generation and extending service life.

Functionality

Pulse-to-Displacement Conversion

A core function of the hybrid stepper motor is its ability to translate electrical pulse signals into precise mechanical movement. Each pulse corresponds to a fixed angular or linear displacement, allowing for accurate positioning without the need for feedback sensors in many applications. This open-loop control capability simplifies system design while maintaining high precision.

Stable and Low-Noise Operation

The precision-machined rotor and optimized stator design minimize vibration and noise during operation. The motor’s smooth rotation is enhanced by the even distribution of magnetic force, making it suitable for applications such as stage lighting and medical equipment where quiet, steady movement is essential.

Adjustable Speed and Torque

The NEMA34 stepper motor offers flexible speed control through pulse frequency adjustment, allowing it to adapt to different application requirements—from high-speed positioning in automation lines to slow, precise movement in testing equipment. Its high holding torque ensures that the motor maintains position securely when not in motion, preventing drift in precision applications.

Characteristic Advantages

High Precision Positioning

The precision stepper motor delivers exceptional positioning accuracy, with minimal step error and repeatability. This makes it ideal for applications such as laser engraving, 3D printing, and CNC machinery, where even slight deviations can affect product quality.

Reliable and Durable Performance

The use of high-grade magnetic steel and industrial-grade materials ensures the motor’s durability and long service life. Rigorous testing during production—including component inspection and final assembly testing—guarantees consistent performance and resistance to wear and tear.

Low Noise and Vibration

Compared to conventional stepper motors, the NEMA34 hybrid stepper motor operates with significantly lower noise and vibration. This advantage is attributed to its coated rotor, optimized design, and balanced magnetic configuration, making it suitable for noise-sensitive environments.

Versatile Adaptability

The motor’s compatibility with various control systems and voltage requirements makes it highly versatile. It can be integrated into a wide range of equipment, from small automation devices to large industrial machinery, and supports custom configurations to meet specific application needs.

Application Areas

3D Printing and Laser Engraving

In 3D printers, the NEMA34 stepper motor controls the movement of the print head and build plate with precise positioning, ensuring layer accuracy and print quality. In laser engravers, it enables smooth, precise movement of the laser beam, creating detailed designs on various materials.

Medical and Healthcare Equipment

The motor’s high precision and low noise make it suitable for medical devices such as diagnostic scanners, rehabilitation equipment, and drug delivery systems. It provides the accurate motion control needed for critical medical procedures and patient care.

Industrial Automation and Robotics

In industrial automation lines and robotic systems, the hybrid stepper motor powers conveyor belts, robotic arms, and positioning stages. Its fast response time and high precision ensure efficient, accurate operation of automated processes.

Textile and Stage Equipment

In textile machinery, the motor controls the movement of yarn and fabric with consistent speed and tension. In stage lighting and sound equipment, it enables precise positioning of lights and speakers, enhancing the quality of performances and events.