Product Introduction

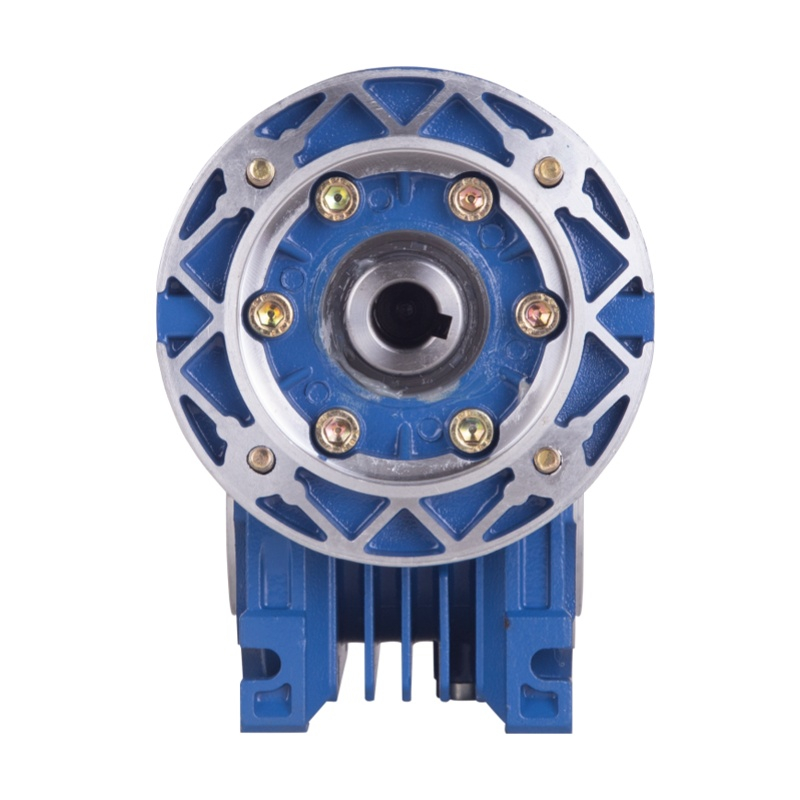

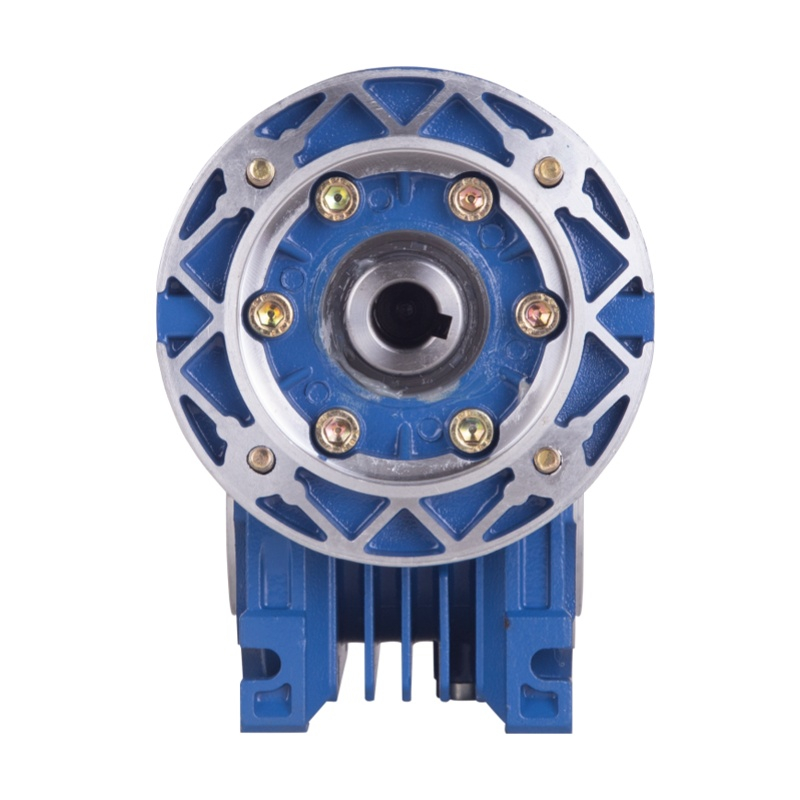

The Worm Gearbox, manufactured by Shenglin Transmission Technology (Ningbo) Co., Ltd., is a high-performance mechanical power transmission device designed to meet the diverse needs of industries worldwide. Renowned for its efficiency, durability, and precision, this worm gearbox is an integral component for applications requiring speed reduction, torque enhancement, and compact design. With its advanced engineering and innovative features, the worm gearbox stands out in the market, providing reliable solutions for a wide range of industrial operations.

The company also offers complete customization services, tailoring the gearbox design to specific requirements, making it the perfect choice for OEM manufacturing and specialized industrial needs.

Product Specifications

The following table summarizes the key specifications of Shenglin's Worm Gearbox:

| Parameter | Value |

| Gearing Arrangement | Worm |

| Output Torque | 2.6-1760 N.m |

| Input Speed | 750~3500 rpm |

| Output Speed | 14~280 rpm |

| Ratio Options | 7.5, 10, 15, 20, 25, 30, 40, 50, 60, 80, 100 |

| Housing Material | Aluminum & Cast Iron |

| Weight | 2 KG |

| Input Form | IEC Flange for Mounting Motor |

| Output Shaft Type | Hollow Shaft / Solid Shaft / Flanged Shaft |

| Mounting Orientation | Horizontal / Vertical / Flange Mounted |

| Maximum Input Horsepower | 0.08 HP ~ 29 HP |

| Color | RAL5010 (Blue) or K9149 (Gray) |

| Certification | CE, ISO9001 |

| Customization Support | OEM, ODM |

| Warranty | 1 Year After Vessel Date |

Product Features

High Gear Ratio

Shenglin's worm gearbox can achieve high gear ratios in a single stage, enabling significant speed reduction in compact dimensions. This makes it ideal for applications where space is limited but substantial torque is required.

Self-Locking Mechanism

The worm gearbox provides inherent self-locking capabilities, ensuring that the gear remains in position when the input shaft is stationary. This feature is particularly beneficial for conveyor systems, hoisting equipment, and other systems requiring back-driving prevention.

Quiet Operation

Thanks to the sliding contact mechanism between the worm and the worm wheel, the gearbox operates with minimal noise, making it suitable for environments where low noise levels are critical.

Compact and Versatile Design

The compact design of the worm gearbox allows it to be installed in multiple orientations (horizontal, vertical, flange-mounted) depending on the application. The versatility of output shaft options enhances its adaptability.

Durability and Efficiency

The robust material selection, including aluminum and cast iron housing, ensures durability, while modern lubrication techniques improve operational efficiency. Proper alignment and lubrication can achieve high energy efficiency levels.

Product Quality Control

Shenglin Transmission Technology emphasizes rigorous quality control at every production stage. Key steps include:

Material Inspection: High-quality materials are sourced and tested for durability and wear resistance.

Precision Manufacturing: The gearbox components are processed using advanced CNC machining and gear grinding technology to ensure accuracy.

Assembly Testing: Each gearbox undergoes a series of functional and performance tests to verify torque, speed, and noise levels.

Final Quality Assurance: Products are certified with CE and ISO9001 standards before shipment.

Product Production Process

The production process of Shenglin’s worm gearbox includes the following steps:

Material Preparation: High-quality aluminum and cast iron are selected for the housing and gears.

CNC Machining: Precision machining ensures tight tolerances and accurate gear alignment.

Gear Grinding and Polishing: To minimize friction and enhance efficiency.

Assembly: Components are assembled by skilled technicians in a clean environment.

Performance Testing: Each gearbox undergoes torque, speed, and noise testing.

Packaging and Delivery: Products are securely packed for safe transportation.

Service and Support

Shenglin offers comprehensive pre-sale, sale, and after-sale services:

Pre-Sale: Prompt response to inquiries, detailed product recommendations, and support with customization requirements.

During Sale: Real-time updates on production and delivery status.

After-Sale: Active troubleshooting support, quality assurance, and customer feedback handling.

Why Choose Us?

Experience and Expertise: Over 20 years of industry experience.

Customization Support: Tailored solutions to meet specific application requirements.

Global Reach: Trusted by clients across Asia, Africa, and Latin America.

Innovative Technology: Cutting-edge manufacturing techniques ensure superior performance.

Reliable Customer Service: Dedicated team for quick and effective solutions.

FAQ

Q: Are you a factory or a trading company?

A: We are an industry and trade-integrated company based in Ningbo, China.

Q: How to place an order?

A: Make an inquiry → Discuss customization → Confirm design → Sample approval → Sign contract → Mass production → Delivery.

Q: What shipping methods are available?

A: Express, sea, and air shipping options are available.

Q: What is the delivery time?

A: Stock/sample orders are shipped within 7 days, while custom orders take about 30 days.

By combining cutting-edge technology, exceptional quality, and dedicated customer service, Shenglin's Worm Gearbox is your reliable partner for industrial power transmission needs.