Product Overview

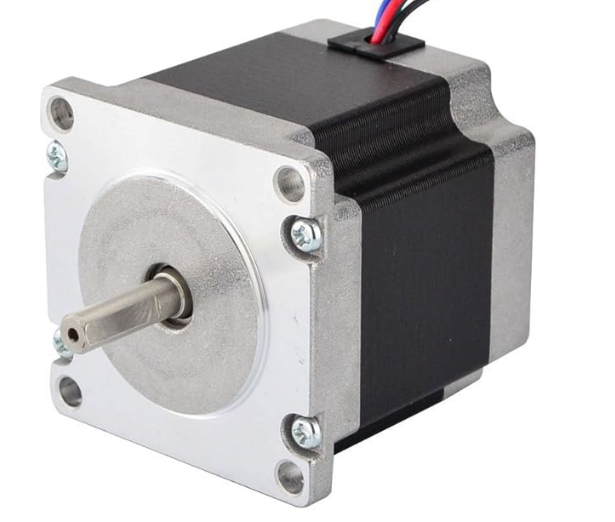

The 57BYG/86BYG Series Stepper Motor with Driver, developed by SL, is a high-torque, precision drive solution tailored for embroidery machines, CNC equipment, and automated systems. Available in models like 57BYG250-41h and NEMA 17 Series, this two-phase hybrid stepper motor combines the advantages of permanent magnet and variable reluctance designs—featuring strong detent torque, accurate step control, and stable operation. Paired with a digital stepper driver (supporting current adjustment from 2.00A to 6.00A), it delivers reliable performance for applications requiring precise positioning, such as embroidery pattern stitching and CNC machining. With a monthly production capacity of 300,000 units, we ensure consistent supply for large-scale manufacturing needs.

Product Advantages

High Torque for Heavy-Duty Tasks

As a hybrid stepper motor, it integrates permanent magnet rotors and toothed stator/rotor cups (50 teeth per cup, displaced by 3.6°), generating strong torque to drive embroidery machine needles or CNC toolheads, even under load.

The driver supports peak currents up to 7.20A, ensuring sufficient power output for high-torque requirements, avoiding step loss during high-speed operation.

Precise Positioning Control

The motor’s two-phase construction (4 poles per phase) and precise step angle design enable accurate position adjustment, critical for embroidery machines to create fine patterns and CNC equipment to achieve high machining precision.

The digital driver offers adjustable current levels (2.00A-6.00A rated, 2.40A-7.20A peak) via SW1-SW4 switches, allowing customization based on load demands to optimize precision and energy efficiency.

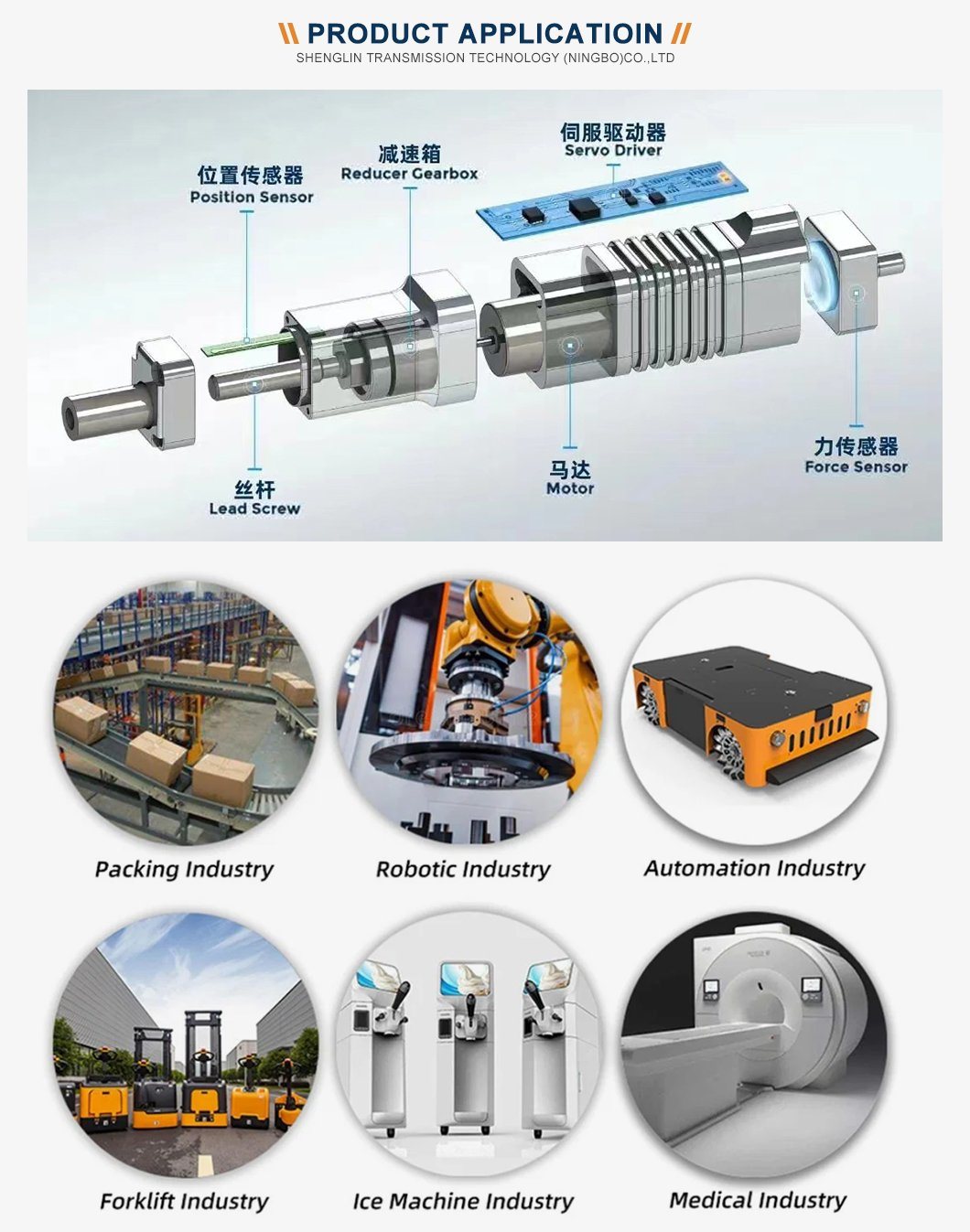

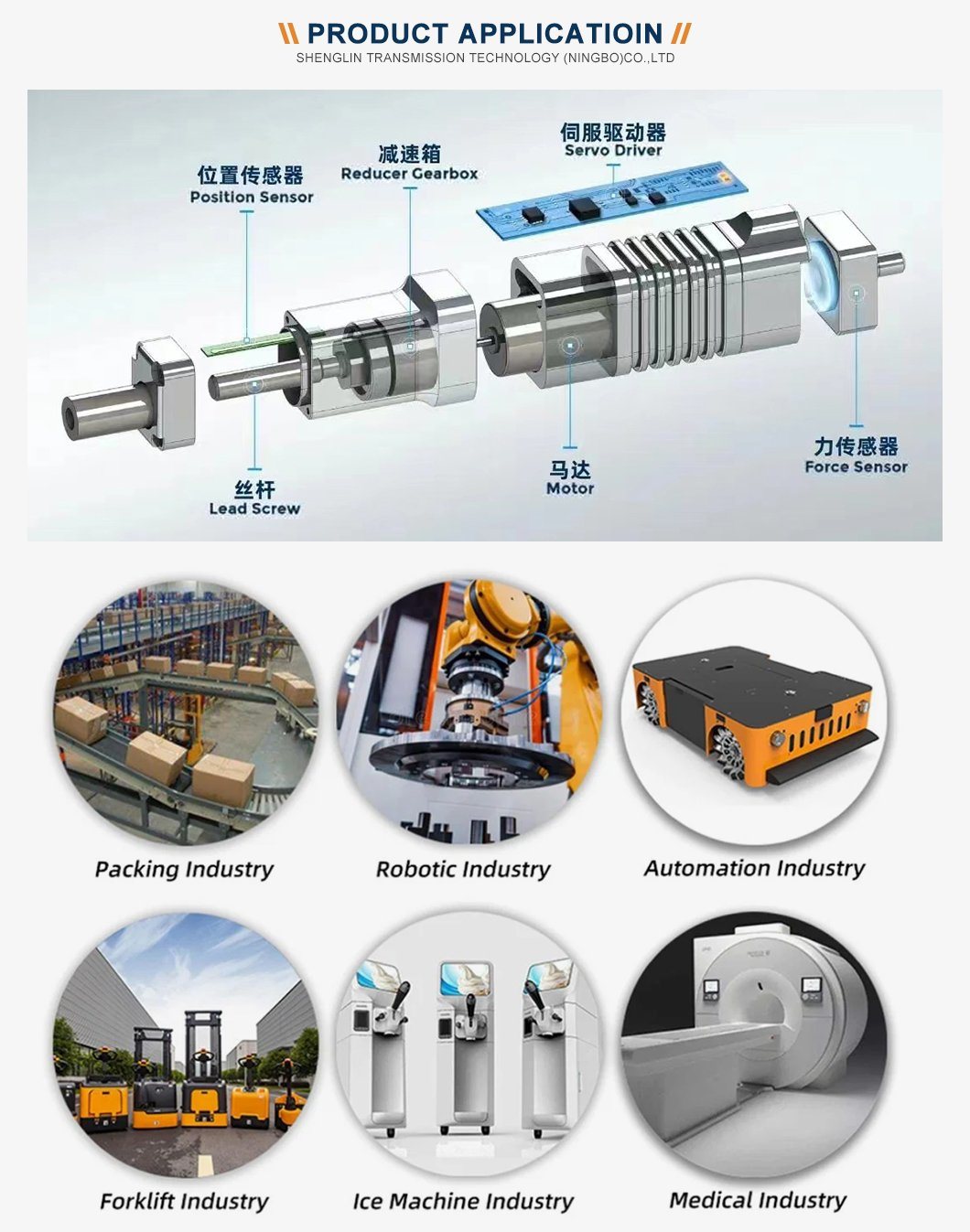

Wide Compatibility & Versatility

Suitable for embroidery machines (its primary application) and CNC equipment (e.g., 24V CNC systems); also compatible with automated production lines, robotics, and packaging machinery, meeting diverse industrial needs.

Supports different encoder types (e.g., differential encoders) for closed-loop control, enhancing positioning accuracy in high-precision scenarios.

Technical Specifications

Model Range: 57BYG Series (e.g., 57BYG250-41h), 86BYG Series, and NEMA 17 Series; HS Code: 8501109990 for customs clearance.

Motor Type: Two-phase hybrid stepper motor, combining permanent magnet and variable reluctance technologies; rotor cups with 50 teeth (displaced by 3.6°) for precise stepping.

Driver Current: Rated current ranges from 2.00A to 6.00A, with peak current from 2.40A to 7.20A; adjustable via SW1 (on/off), SW2 (on/off), SW3 (on/off), and SW4 (off for half current mode) switches.

Application Equipment: Primarily for embroidery machines; also compatible with 24V CNC systems, automated conveyors, robotic arms, and packaging machinery in the automation and robotics industries.

Production Capacity: 300,000 units per month, ensuring large-order fulfillment and timely delivery; all motors undergo strict quality testing before shipment.

Electrical Configuration: Designed for AC power, with standard wiring (e.g., red for A+, black for A-, green for B+, blue for B-) for easy installation and connection to drivers.

Why Choose Us

High Precision for Specialized Needs: Tailored for embroidery machines (requiring fine pattern control) and CNC equipment, the motor’s hybrid design and adjustable driver ensure unmatched positioning accuracy, reducing product defects.

Mass Production Capacity: With 300,000 units produced monthly, we can handle large orders from embroidery machine manufacturers or CNC suppliers, avoiding supply chain delays.

Easy Integration: Standard wiring and compatible encoder interfaces simplify installation, allowing quick integration into existing production lines without extensive modifications.

Proven Quality: As an SL-branded product, it undergoes rigorous testing (e.g., torque, current stability, and durability) to meet international standards, ensuring reliable performance in long-term operation.

FAQ

Q1: Can this stepper motor be used for CNC routers besides embroidery machines?

A1: Yes. It is fully compatible with 24V CNC systems, including CNC routers, thanks to its high torque and precise step control, making it suitable for cutting or engraving tasks that require accurate positioning.

Q2: How do I adjust the driver’s current for different loads?

A2: You can adjust the current via the SW1-SW3 switches on the driver. For example, setting SW1 to "on", SW2 to "off", and SW3 to "off" gives a rated current of 6.00A (peak 7.20A) for heavy loads; setting SW4 to "off" enables half-current mode for light loads, saving energy.

Q3: What is the service life of this stepper motor?

A3: Under normal use (proper maintenance and no overloading), the motor has a service life of 5,000+ operating hours. The hybrid design reduces wear on internal components, extending its lifespan compared to conventional stepper motors.

Q4: Does the motor come with a driver, or do I need to purchase it separately?

A4: The product is sold as a set (motor + driver), so you don’t need to purchase the driver separately. The driver is pre-configured with basic parameters, allowing you to use it immediately after wiring.