Product Overview

This motor integrates a high-power DC motor with a precision-machined geared box, delivering the consistent torque and speed control required for demanding industrial tasks. Unlike standard motors, it balances robust power (550W to 800W) with flexible adaptability, making it suitable for both stationary and semi-mobile equipment. Whether powering conveyor belts, mixers, or heavy machinery, the SL ZY114S-120 DC Motor ensures long-term reliability, thanks to its premium build and compliance with industrial quality standards. It is a core product in SL TECH’s DC Motor lineup, designed to fill the gap between low-torque small motors and high-cost industrial alternatives.

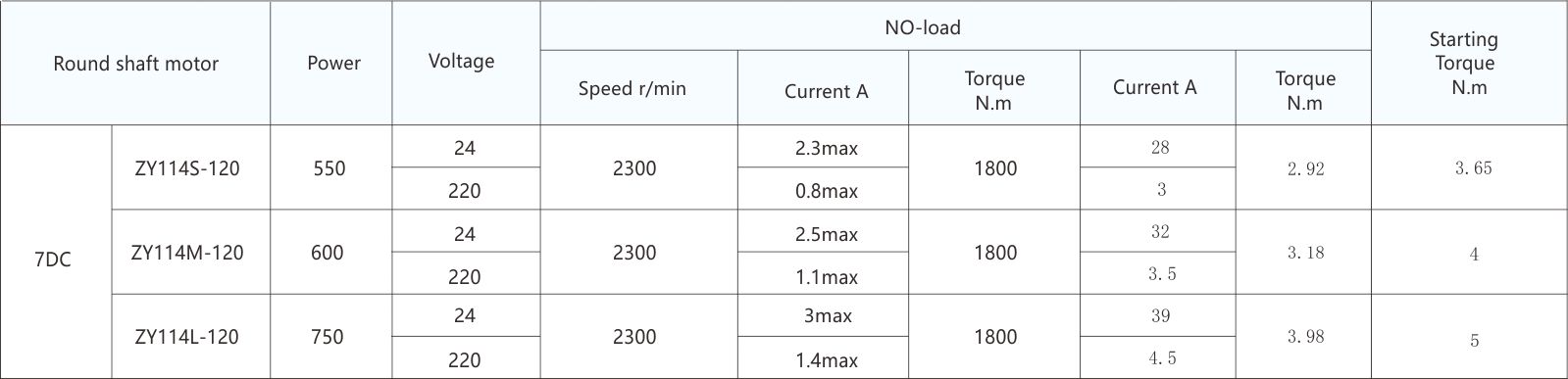

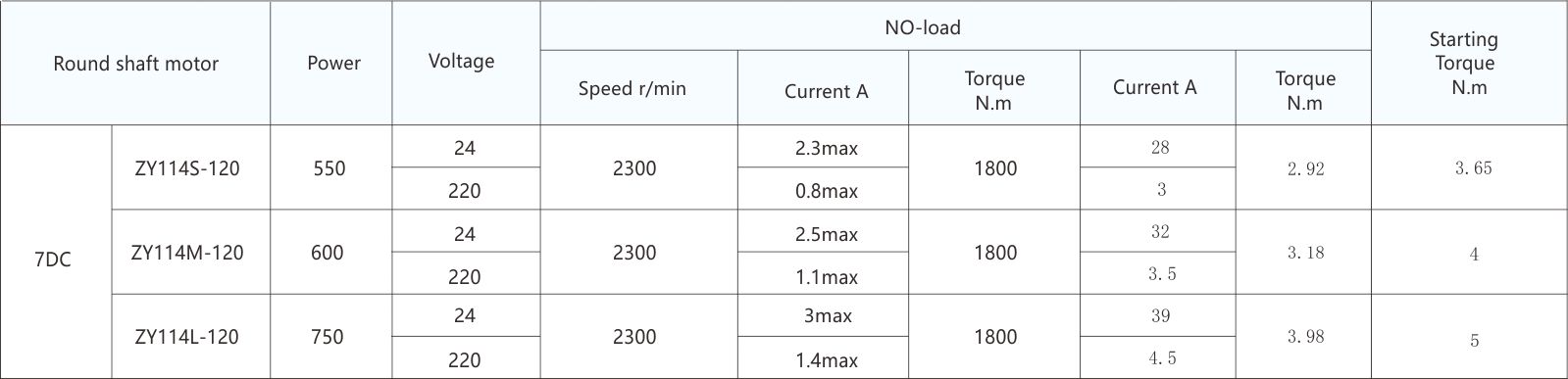

Technical Parameters

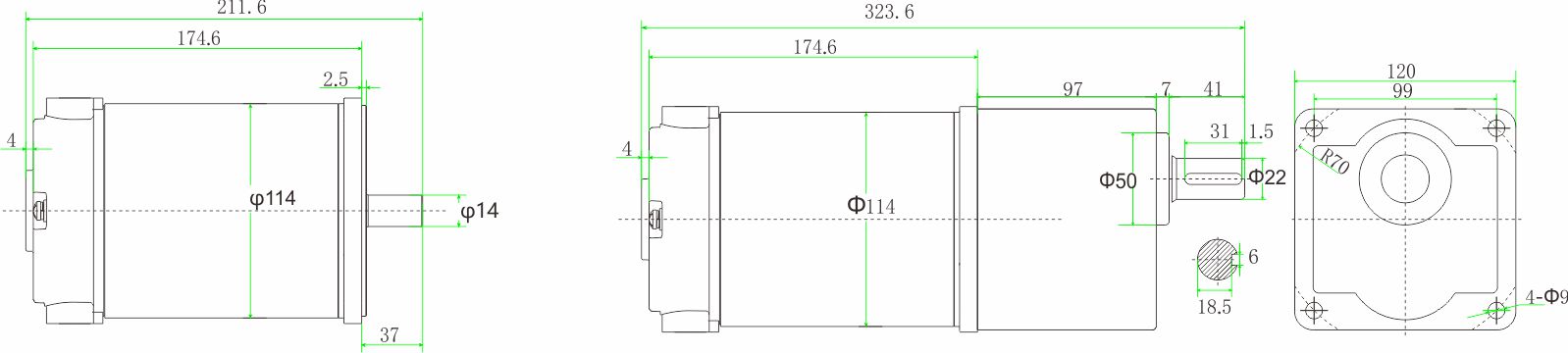

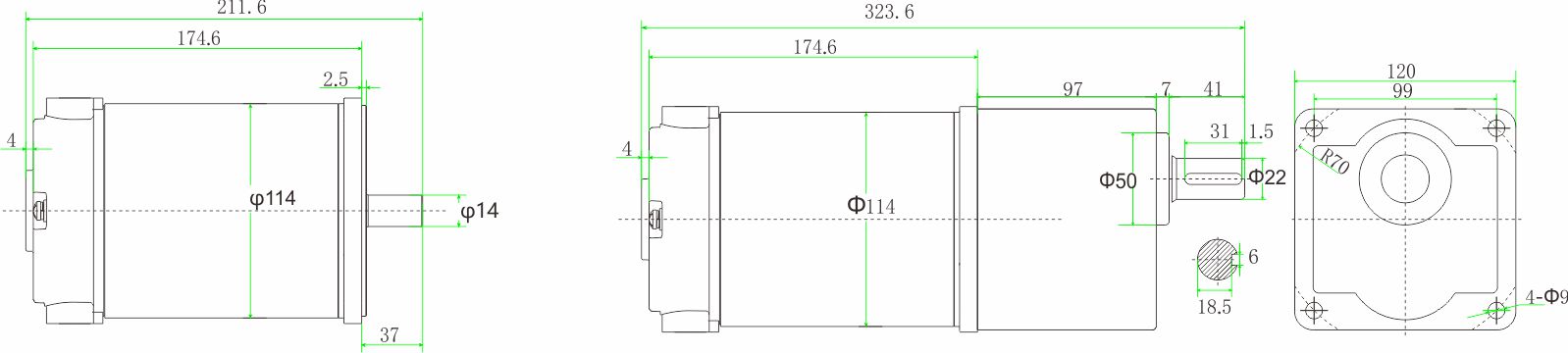

Overall dimensions

Motor voltage, power and speed will be customized accrding to his requestment under the allowed circumstance of adoptable dimension.

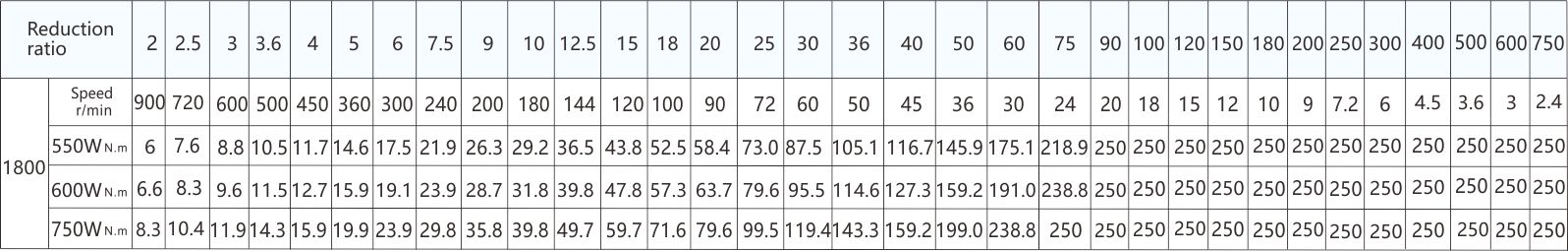

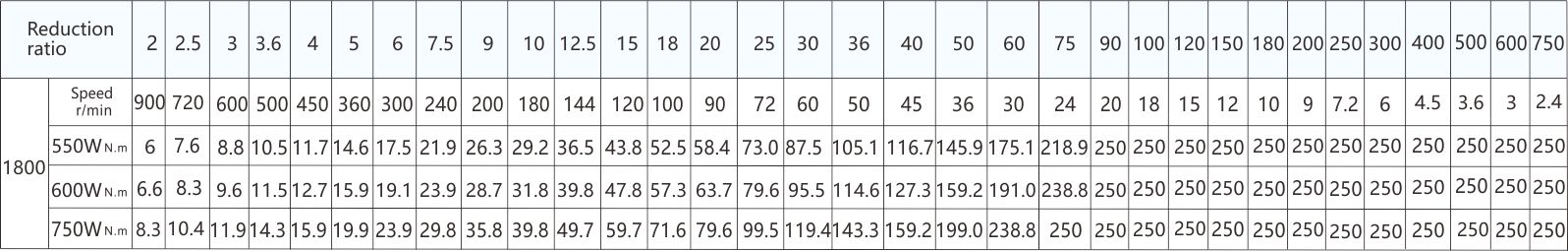

Reduction Motor Max Allowable Torque

Wiring diagram of motor

Functionality

The High Torque 550W~800W DC Motor with Geared Box combines core motor performance with practical features to meet industrial needs, organized into three key functional areas:

Torque & Speed Regulation

At its core, the motor delivers high torque output—a critical feature for moving heavy loads or driving resistance-heavy equipment like grain conveyors or pharmaceutical mixers. The integrated geared box allows precise adjustment of the gear ratio, translating the motor’s raw speed into slower, more powerful rotational force. This means the motor can adapt to tasks requiring either high speed (e.g., light material transport) or maximum torque (e.g., heavy machinery lifting).

Safety & Insulation Protection

Safety is prioritized through rigorous insulation design. The Class F insulation ensures the motor operates safely even at temperatures up to 180°C, preventing overheating in long-duration use. Additionally, the motor meets strict insulation resistance (≥20 MΩ) and voltage tolerance (1.5kV) standards, reducing the risk of electrical faults in wet or dusty industrial environments.

Installation Adaptability

The motor’s customizable lead wire (length, model) and compact design simplify integration into existing equipment. Whether mounted on horizontal frames (e.g., manufacturing assembly lines) or vertical structures (e.g., tunnel engineering pumps), it fits seamlessly without extensive modifications. The standard UL1015 AWG20 wires also ensure compatibility with most industrial wiring systems.

Characteristic Advantages

What sets the SL ZY114S-120 DC Motor apart from competitors is its balance of performance, durability, and flexibility—key advantages for industrial buyers:

High Performance

Wide power range (550W~800W): Covers mid-to-high power needs without requiring multiple motor models.

Precision gear ratio control: The 2K~300K range eliminates the need for external speed reducers, reducing equipment complexity and cost.

Stable speed output: Even under variable loads (e.g., fluctuating material weights in animal husbandry feeders), the motor maintains consistent speed to avoid production delays.

Durability & Reliability

Harsh environment resistance: The -10°C to 40°C operating temperature range and dew-free design make it suitable for outdoor or humid settings like ship decks or environmental protection water treatment systems.

Long service life: High-quality insulation and robust wiring minimize wear and tear, reducing maintenance frequency and total ownership cost.

Flexible Customization

SL TECH offers customizable parameters (voltage, lead wire, gear ratio) to match unique application needs. This is a major advantage for industries with non-standard equipment, such as specialized chemical reactors or custom tunnel engineering machinery, where off-the-shelf motors often fall short.

Application Areas

The High Torque 550W~800W DC Motor with Geared Box is versatile enough to serve seven key industrial sectors, leveraging its torque, durability, and adaptability:

Manufacturing Industry

Ideal for powering assembly line conveyors, robotic arms, and packaging machines. Its stable speed control ensures consistent production rates, while high torque handles heavy component transport.

Animal Husbandry

Used in feed mixers, manure handling systems, and livestock cage lifters. The motor’s resistance to dust and variable loads makes it reliable in farm environments.

Chemical & Pharmaceutical Industries

Suitable for mixing tanks, liquid transfer pumps, and capsule-filling machines. The insulation protection prevents contamination from chemical vapors and ensures compliance with hygiene standards.

Environmental Protection Industry

Drives water treatment pumps, waste incinerator feeders, and air filtration systems. Its ability to operate in dew-free, dusty conditions aligns with the demands of waste management facilities.

Grain & Oil Machinery

Powerful enough to run grain elevators, oil pressers, and seed cleaners. The high torque output handles dense, heavy grain loads without stalling.

Ship Business

Mounted on shipboard equipment like cargo winches, bilge pumps, or anchor motors. Its compact design and corrosion-resistant wiring withstand maritime humidity and vibration.

Tunnel Engineering

Used in tunnel boring machine (TBM) auxiliary systems, ventilation fans, and material transport carts. The motor’s durability and temperature resistance cope with the harsh, enclosed tunnel environment.