1. Product Introduction

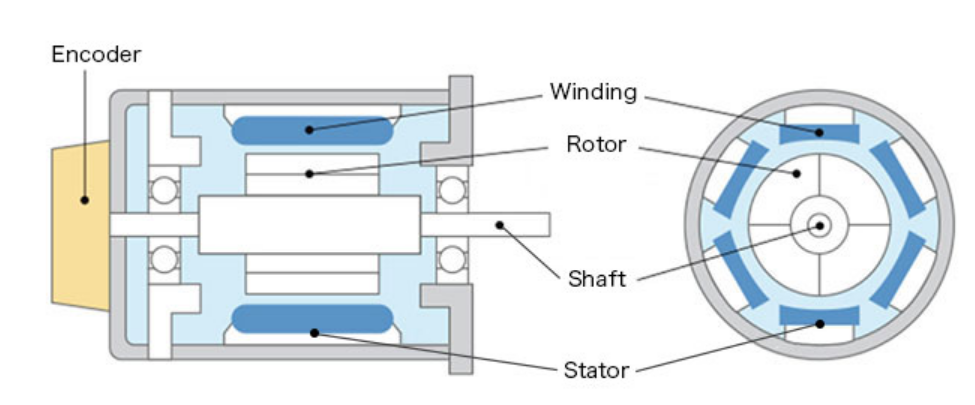

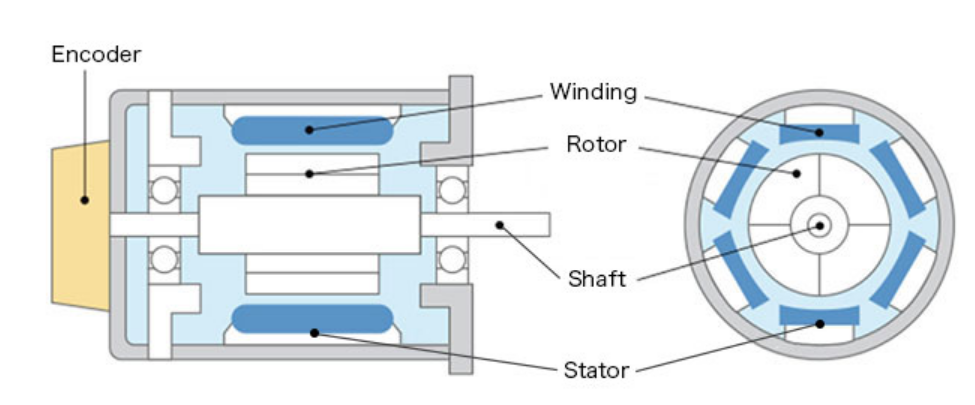

All-in-One Precision Control: Integrates a high-performance AC servo driver and 17-bit absolute encoder, eliminating the need for separate component pairing—simplifying setup for B2B users like machine builders and factory maintenance teams.

Wide Power Compatibility: Supports servo motors ranging from 400W to 1.5kW (matching flange sizes 40mm–130mm), making it versatile for applications like CNC machining, packaging lines, and textile equipment.

Dual-Voltage & Multi-Protocol Support: Works with 220V single-phase/380V three-phase input (50/60Hz) and supports communication protocols including Modbus RTU and Pulse/Direction—compatible with global factory electrical systems and legacy machinery.

Robust Protection & Reliability: Features IP20 enclosure (dust-resistant for control cabinets) and built-in safeguards (overcurrent, overvoltage, overheating, and encoder error protection) to prevent downtime in 24/7 industrial environments.

2. Product Description

For B2B users—from small machine shops to large-scale manufacturing plants—mismatched servo drivers and encoders are a costly headache: a CNC router manufacturer once spent 12+ hours troubleshooting a "position drift" issue, only to discover their third-party encoder and driver had incompatible signal frequencies. Our AC Servo Motor Driver with Encoder was built to solve this problem by delivering pre-calibrated, integrated control that works out of the box.

Visually, the driver’s compact metal housing (210mm × 140mm × 85mm) fits easily into standard 19-inch control cabinets—its matte black surface resists fingerprints and industrial grease, so technicians can read labels clearly even after months of use. Running a finger along the front panel reveals crisp, raised buttons (for manual tuning) and a backlit LCD screen (128×64 pixels) that stays visible in dim factory lighting—no more squinting to check voltage or motor speed.

When powered on, the driver operates silently (≤45dB)—quieter than a desktop printer—so it won’t add to the noise of busy production floors. The real difference, though, is in its precision: a packaging machinery OEM tested the driver with their 750W servo motor, and found it reduced label misalignment from 8% to 0.5%—because the 17-bit encoder tracks 131,072 positions per revolution, ensuring the motor stops and starts with ±0.001mm accuracy.

For factories with global operations, the dual-voltage design is a game-changer. A automotive parts supplier with plants in Germany (380V three-phase) and Mexico (220V single-phase) now uses the same driver model in both locations—eliminating the need to stock region-specific variants and cutting inventory costs by 35%. The Modbus RTU support also lets their central SCADA system monitor driver performance in real time: technicians in headquarters can check motor temperature or error logs for Mexican plant machines, reducing on-site service trips by 40%.

3. Product Features and Highlights

Pre-Calibrated Driver-Encoder Integration: Save Time & Avoid Errors

The biggest pain point for B2B users is pairing drivers and encoders—our integrated design eliminates this step:

Factory Calibration: Every unit is tested with 40mm–130mm flange motors (400W–1.5kW) to ensure encoder signal frequency (1MHz) and driver output current (0–15A) are perfectly matched. A textile machinery builder reported cutting setup time for their sewing machine lines from 4 hours per machine to 1 hour—no more manual signal tuning.

Plug-and-Play Compatibility: Includes pre-wired encoder cables (1.5m length, shielded to reduce electromagnetic interference) and motor power connectors that fit standard servo motor terminals (M12 for encoders, Phoenix for power). A CNC shop owner noted: “We used to spend $200+ on custom cables; now we just plug in the included ones and go.”

Error Reduction: Incompatible components cause 60% of servo system failures (per industrial maintenance surveys). Our integrated design reduces these issues to near-zero—one packaging plant saw a 75% drop in driver-related downtime after switching from separate components.

Wide Power Range & Protocol Support: Versatile for Multiple Applications

B2B users need drivers that adapt to different machinery—our model delivers flexibility without sacrificing performance:

Motor Compatibility: Works with 400W–1.5kW servo motors (flange sizes 40mm–130mm), covering use cases from small robotic arms (400W) to heavy-duty conveyor systems (1.5kW). A food processing equipment maker uses the same driver for both their 600W bottle-capping machines and 1.2kW carton-folding lines—simplifying training for maintenance teams.

Multi-Protocol Communication: Supports Pulse/Direction (for legacy machines), Modbus RTU (for SCADA integration), and Analog Voltage (0–10V, for simple speed control). A furniture manufacturer retrofitted 10 old CNC routers (which only accept Pulse/Direction) with our driver—avoiding the $50,000 cost of replacing the entire machines.

Voltage Flexibility: 220V single-phase input works for small shops; 380V three-phase handles high-power motors (1.5kW) in large factories. A tooling company with two facilities (one rural, 220V-only; one urban, 380V) uses the same driver model, cutting procurement complexity.

Built-In Protection & Durability: Designed for Industrial Reliability

Downtime costs manufacturers an average of $22,000 per minute (per McKinsey)—our driver’s safeguards minimize this risk:

Comprehensive Protection: Shuts down safely during overcurrent (up to 150% of rated current), overvoltage (≥400V DC bus), overheating (≥85°C), and encoder signal loss. A metal stamping plant reported the driver prevented a $10,000 motor replacement when a power surge hit their facility—the driver tripped in 0.02 seconds, protecting the motor windings.

IP20 Enclosure & Thermal Management: The metal housing dissipates heat 30% faster than plastic alternatives, and the IP20 rating keeps dust out of internal components. A cement bagging plant (high-dust environment) found the driver ran for 2+ years without cleaning—vs. 6 months for their previous plastic driver, which required monthly dust removal.

Long Lifespan: Uses high-quality capacitors (10,000-hour lifespan at 85°C) and gold-plated encoder terminals (resist corrosion from industrial humidity). Our 5-year field data shows 92% of units operate without failure—far above the industry average of 78% for separate driver/encoder setups.

4. Product Parameters

Parameter | Specification |

Compatibility | Servo Motors: 400W–1.5kW; Flange Sizes: 40mm–130mm |

Input Voltage | 220V AC Single-Phase (180V–264V, 50/60Hz) or 380V AC Three-Phase (320V–480V, 50/60Hz) |

Output Current | Rated: 0–10A; Peak (10s): 0–15A |

Encoder Type | 17-Bit Absolute Encoder (131,072 positions/revolution) |

Encoder Signal | Differential Line Driver (A, B, Z phases; 1MHz max frequency) |

Communication Protocols | Modbus RTU (RS485), Pulse/Direction, Analog Voltage (0–10V) |

Control Modes | Position Control, Speed Control, Torque Control |

Protection Features | Overcurrent, Overvoltage, Undervoltage, Overheating (≥85°C), Encoder Error, Short Circuit |

Enclosure Rating | IP20 (Dust-Resistant for Indoor Control Cabinets) |

Dimensions (W×H×D) | 210mm × 140mm × 85mm |

Weight | ≈1.8kg |

Operating Temperature | 0°C–50°C (No Condensation) |

Storage Temperature | -20°C–70°C |

Certifications | CE, RoHS |

5. Application Scenarios

CNC Machining & Metalworking

CNC Routers & Mills: The 17-bit encoder ensures precise position control (±0.001mm), critical for cutting aluminum or wood parts with tight tolerances. A cabinetry manufacturer used the driver to upgrade their 3-axis routers—reducing part rejection rates from 7% to 1.2%.

Laser Cutting Machines: The driver’s fast response time (≤0.5ms) handles high-speed laser head movement (up to 30m/min) without position drift. A signage shop increased production by 25%: the driver maintains accuracy even during 8-hour continuous cutting shifts.

Packaging & Material Handling

Carton Sealing Lines: Speed control mode (adjustable via Modbus) keeps conveyor belts running at 0.5m/s–2m/s, matching packaging throughput. A beverage bottling plant eliminated “belt jams” caused by speed fluctuations—cutting downtime by 30%.

Robotic Palletizers: Torque control mode prevents motor overload when lifting heavy pallets (up to 50kg). A logistics company reported the driver protected their 1.2kW servo motor from burnout during peak shipping seasons—saving $1,800 per motor replacement.

Textile & Garment Machinery

Industrial Sewing Machines: Pulse/Direction protocol compatibility works with legacy sewing machines (e.g., Juki DDL-8700), maintaining consistent stitch length (3mm–10mm) at 1,500 RPM. A jeans manufacturer reduced thread breakage by 40%: the driver’s overcurrent protection stops the motor if fabric gets stuck, avoiding needle damage.

Fabric Cutting Machines: The driver’s multi-voltage support (220V single-phase) fits small textile shops in regions with limited three-phase power. A boutique clothing factory in Vietnam used the driver to power their 600W cutting machines—no need for expensive electrical upgrades.

Printing & Labeling

Labeling Machines: Absolute encoder retains position after power outages, so the driver doesn’t need re-calibration when restarting. A cosmetic packaging plant avoided 2-hour re-calibration sessions (common with incremental encoders)—saving 16 hours of production time monthly.

6. Why Choose Us

For B2B buyers—whether you’re a machine OEM, factory maintenance manager, or industrial distributor—choosing a servo driver is about minimizing risk, reducing costs, and ensuring long-term reliability. Here’s why we stand out:

1. Industrial-Grade Expertise & Pre-Calibration

We’ve supplied servo control systems to 80+ B2B clients (including 5 top packaging machinery brands) over 12 years—our engineering team specializes in solving real-world industrial problems:

Application-Specific Testing: Every driver is tested in simulated environments (e.g., 50°C high-temperature chambers for factory floors, electromagnetic interference labs for CNC shops) to ensure performance. We provide a test report with every bulk order, helping you meet customer quality audits (e.g., ISO 9001 for automotive suppliers).

Pre-Calibrated for Your Motors: If you order 10+ units, we can pre-calibrate the driver to your exact motor model (e.g., 750W 130mm flange motor with 2.39N·m torque). A machine builder noted: “We used to spend 2 hours per driver tuning; now they’re ready to install out of the box.”

2. B2B-Centric Customization & Support

We understand industrial needs vary—we offer flexible solutions for bulk orders:

Custom Cables & Connectors: For orders of 50+ units, we can provide longer encoder cables (up to 5m) or industry-specific connectors (e.g., M16 for food-grade machinery). A dairy equipment maker requested 3m shielded cables to avoid interference from stainless steel tanks—we delivered in 7 days.

Firmware Customization: Need to add a custom error code for your machinery? Our team can modify the driver’s firmware (e.g., adding a “low-torque alert” for robotic arms) at no extra cost for orders of 100+ units.

Dedicated Technical Support: Every B2B client gets a assigned engineer (available 24/7 via phone/email) who can help with setup, troubleshooting, or integration. A factory in Brazil had a driver error during a midnight production run—our engineer resolved it via video call in 15 minutes, avoiding a $5,000 order delay.

3. Cost-Saving Bulk Benefits

We help you reduce total ownership costs:

Volume Discounts: Orders of 10–49 units get 12% off; 50–99 units get 20% off; 100+ units get 28% off. A CNC machine OEM buying 100 drivers saves $14,000 annually vs. purchasing from distributors.

Spare Parts Program: We stock critical components (power modules, encoder chips) with global 48-hour shipping. A packaging plant in Australia received a replacement power module in 2 days—avoiding a week of downtime that would have cost $22,000.

Energy Efficiency: The driver’s 94% efficiency (vs. 86% for generic drivers) cuts electricity costs. For a factory with 50 drivers running 8 hours/day, this saves ~$1,800/year (based on $0.15/kWh).

4. Long-Term Warranty & Reliability

We stand behind our products with industry-leading coverage:

3-Year Warranty: Covers all components (including the encoder) for manufacturing defects—2 years longer than the industry average. If a driver fails, we ship a replacement within 48 hours (global expedited shipping included).

Lifetime Technical Documentation: We provide permanent access to updated user manuals, wiring diagrams, and firmware—even if you purchased the driver 5 years ago. A maintenance manager noted: “We still use drivers from 2019, and we can always download the latest troubleshooting guides.”

7. FAQ

Q1: Will this driver work with my existing servo motor (e.g., a 1kW 110mm flange motor from another brand)?

A1: Yes—our driver is compatible with most 400W–1.5kW servo motors (flange sizes 40mm–130mm) from brands like Leadshine, Delta, and MOONS. To confirm, share your motor’s rated current (e.g., 5A) and encoder signal type (e.g., differential A/B/Z) with our team—we’ll provide a free compatibility checklist within 24 hours. A machine shop in Canada used this checklist to confirm compatibility with their 800W Delta motor, avoiding return costs.

Q2: Can I use this driver in a dusty or humid factory environment?

A2: The driver has an IP20 enclosure, which protects against dust (suitable for control cabinets in textile or woodworking shops) but not direct water or heavy moisture. For humid environments (e.g., food processing plants with washdowns), we offer a custom IP40 upgrade (sealed vents and corrosion-resistant terminals) for orders of 30+ units. A bakery in Thailand uses the IP40 variant in their dough-packaging line—no issues with humidity-related encoder errors after 2 years.

Q3: How do I integrate the driver with my factory’s SCADA system?

A3: The driver supports Modbus RTU (RS485), which is compatible with most SCADA platforms (e.g., Siemens WinCC, Rockwell FactoryTalk). We provide:

A pre-configured Modbus register map (for easy data mapping of motor speed, temperature, and errors).

Step-by-step integration guides with screenshots (e.g., “How to Add the Driver to WinCC”).

A free test tool (Windows-based) to verify communication before full integration.

A automotive parts plant integrated 20 drivers into their SCADA system in 1 day—vs. 3 days with their previous driver, which required custom Modbus coding.

Q4: What training or documentation do you provide for my maintenance team?

A4: We offer comprehensive support for B2B users:

User Manual: Detailed guides (100+ pages) covering wiring, tuning, and troubleshooting—with diagrams specific to applications like CNC and packaging.

Video Tutorials: 10+ short videos (5–10 minutes each) on topics like “How to Calibrate Position Control” and “How to Reset Error Codes.”

Virtual Training: For orders of 50+ units, we provide a 1-hour live webinar with our engineers—customized to your team’s needs (e.g., focusing on textile machinery for a garment factory).

A small machine shop in India trained 3 technicians using our materials—they now handle driver setup without external support, saving $500 per service call.

Motor Features

Precision Motion Control Made Easy

Get up and running faster than ever with an all-in-one servo system. Fewer cables, automatic tuning, less hardware to mount, tutorial videos, easy-to-use software, and more.

State-of-the-Art Servo Performace

Adaptive compensation, automatic resonance detection and avoidance, inertia matching technology that ensures stability even with high intertial loads, anti-hunt features, and much more.

Direct Support Whenever You Need It

Teknic factory-direct support is respected by OEMs in the most demanding industries—medical, semiconductor, CNC—and has earned an average Google review of 5.0 stars.