1. Product Introduction

Tailored for Sewing & Packaging Needs: 750W power and 3000rpm speed balance efficiency and precision—ideal for high-speed sewing (e.g., garment production) and continuous packaging (e.g., film wrapping, carton sealing).

Dual-Voltage Compatibility: Works with 220V single-phase (200-240V, 50/60Hz) grids, eliminating the need for 3-phase power and simplifying integration into small-to-medium textile/packaging facilities.

17-Bit Encoder Precision: Delivers position accuracy within ±0.002mm, ensuring consistent stitch length in sewing machines and uniform packaging seal pressure—reducing material waste.

Durable & Compact Design: 80mm flange size (NEMA 23 equivalent) fits tight machine enclosures; IP54 protection resists lint (sewing) and dust (packaging), while Class F insulation (155°C) prevents overheating during long shifts.

2. Product Description

For textile factories and packaging plants, a unreliable motor can trigger costly chain reactions: a sewing machine with inconsistent speed ruins 100+ meters of fabric; a packaging line motor that overheats halts production for hours. Our 3000rpm 750W AC Servo Motor was built to solve these pain points, with design choices tailored to the unique challenges of sewing and packaging operations.

Visually, the motor’s 80mm flange is compact—small enough to fit inside the tight compartment of a industrial sewing machine (where space is at a premium) yet sturdy enough to mount securely on packaging line conveyors. Running a finger along the flange edges reveals smooth, CNC-machined surfaces with no burrs, ensuring it aligns perfectly with standard machine brackets without gaps that trap lint or dust. The cast-aluminum housing has a matte, anti-scratch coating; when you grip it, it feels solid but lightweight (≈5.2kg), making installation easy for a single technician—no need for heavy lifting equipment.

When operational, the motor’s quiet performance stands out. Unlike generic motors that emit a harsh whir (70+ dB) that disrupts factory floors, this motor hums softly (≤55dB)—quieter than a conversation—so sewers and packaging operators can work comfortably for 8+ hours without noise fatigue. More importantly, the 17-bit encoder eliminates "speed drift": a garment factory using this motor for denim sewing reported consistent 3mm stitch lengths across 500+ pairs of jeans, compared to their old motor (which varied by ±0.5mm, forcing rework on 15% of orders).

For packaging lines, the motor’s thermal management is a game-changer. Conventional motors often overheat after 4 hours of continuous 3000rpm operation (common in high-speed carton sealing), but our design includes a built-in aluminum heat sink and Class F insulation. A snack packaging plant tested the motor on their film-wrapping line: it ran for 12 hours straight at full load, maintaining 3000rpm without triggering thermal shutdowns—cutting downtime by 60% compared to their previous motor, which required 20-minute cool-down breaks every 3 hours.

The 220V single-phase input is a boon for global B2B buyers. A textile factory in Vietnam (220V) or a packaging plant in Mexico (240V) can deploy the same motor without rewiring or adding converters. This standardization simplifies inventory: a multinational garment brand with factories in 3 countries now stocks one motor model instead of three region-specific variants, reducing storage costs by 40%.

3. Product Features and Highlights

750W Power + 3000rpm Speed: Optimized for Sewing & Packaging

Sewing and packaging demand motors that balance power (to handle tough materials) and speed (to meet production targets)—our motor delivers both:

Sewing Applications: The 750W rating provides enough torque (2.39 N·m continuous) to sew thick fabrics like denim or canvas at 3000rpm, without stalling. A jeans manufacturer increased their sewing line output by 25%: the motor sews 1,200 stitches per minute (SPM) vs. 950 SPM with their old 550W motor, while maintaining stitch consistency.

Packaging Applications: 3000rpm ensures fast material handling—e.g., a carton sealing line using this motor can seal 60 cartons per minute (up from 45 with a slower motor). The motor’s smooth speed control also prevents "jerks" that cause packaging film to tear, reducing material waste by 18% for a beverage bottling plant.

Unlike one-size-fits-all motors, this model’s power/speed ratio is calibrated to avoid overkill (which wastes energy) or underperformance (which slows production)—perfect for the mid-range demands of most sewing and packaging tasks.

17-Bit Encoder: Precision That Cuts Rework

In sewing and packaging, even tiny inaccuracies lead to big losses. Our 17-bit absolute encoder solves this:

Sewing Precision: The encoder tracks 131,072 positions per revolution, ensuring the motor maintains exact speed for consistent stitch lengths. A lingerie factory using the motor for delicate lace sewing reported zero stitch irregularities—down from 8% with their old 12-bit encoder motor, which required hand-trimming flawed seams.

Packaging Accuracy: For tasks like label application, the encoder ensures the motor stops and starts instantly (response time ≤0.1ms), so labels align perfectly with package edges. A cosmetic brand reduced label misalignment from 10% to 1% after switching to this motor, avoiding costly rejections from retailers.

Unlike incremental encoders that lose position during power outages, the absolute encoder retains settings. For a 24/7 packaging line, this means no need to re-calibrate after a brief power dip—saving 30+ minutes of downtime per incident.

IP54 Protection + Class F Insulation: Built for Factory Environments

Sewing factories are filled with lint; packaging plants have dust and occasional coolant splashes—our motor resists these hazards:

IP54 Rating: The housing seals out lint (which clogs motor vents) and low-pressure water jets (used to clean packaging lines). A towel manufacturer reported no motor failures in 2 years of use—compared to 4 failures per year with their old IP44 motor, which required monthly lint cleaning.

Class F Insulation: The windings withstand temperatures up to 155°C, preventing burnout during long shifts. Thermal tests show the motor runs at just 70°C after 10 hours of continuous 3000rpm operation—well below the insulation limit.

The cast-aluminum housing also acts as a heat sink, dissipating heat 25% faster than plastic housings. This is critical for sewing machines, where the motor is enclosed in a tight space with little airflow—no more overheating that warps fabric or damages machine parts.

Compact 80mm Flange: Fits Tight Machine Spaces

Sewing machines and small packaging line components have limited space—our 80mm flange (NEMA 23 equivalent) solves this:

Sewing Machine Compatibility: The compact design fits inside the motor compartment of industrial sewing machines (e.g., Juki or Brother models) without modifying the machine’s frame. A garment factory retrofitted 20 sewing machines with this motor in 1 day—compared to 3 days for a larger 110mm flange motor, which required cutting and rewelding the machine housing.

Packaging Line Flexibility: The small footprint lets the motor mount on narrow conveyor frames (common in snack or cosmetic packaging lines). A pharmaceutical packaging plant used the motor to power their blister-pack sealing unit—its compact size allowed them to add an extra sealing station without expanding the line’s footprint.

4. Product Parameters

Parameter Specification

Power Rating 750W (Continuous); 1.5kW (Peak, 10s)

Rated Speed 3000rpm

Torque 2.39 N·m (Continuous); 7.17 N·m (Peak)

Voltage 220V AC Single-Phase (200-240V, 50/60Hz)

Encoder 17-Bit Absolute Encoder (131,072 positions/rev)

Position Accuracy ±0.002mm

Flange Size 80mm (NEMA 23 Equivalent)

Shaft Diameter 12mm (Precision-Ground, with Keyway)

Protection Class IP54 (Dust/Lint/Water-Jet Resistant)

Insulation Class Class F (155°C Max Temperature)

Operating Temperature -10°C to 60°C

Weight ≈5.2kg

Mounting Type Flange-Mounted (4x M6 Mounting Holes)

Compatibility Industrial Sewing Machines (Denim, Canvas, Lace), Packaging Lines (Carton Sealing, Film Wrapping, Label Application)

5. Application Scenarios

Industrial Sewing Machines

Denim & Heavy Fabric Sewing: The 750W power and 2.39 N·m torque handle thick materials like denim or canvas without stalling. A jeans factory uses the motor for waistband sewing—producing 250 pairs per hour (up from 200 with their old motor) with consistent stitch tension.

Lingerie & Delicate Fabrics: The 17-bit encoder ensures precise speed control (100-3000rpm adjustable), preventing stretched or broken threads when sewing lace or silk. A lingerie brand reduced thread breakage by 70%, cutting material waste and rework time.

Quilting Machines: The motor’s smooth speed transitions let quilting machines create intricate patterns (e.g., 5mm stipple quilting) without uneven spacing. A bedding manufacturer reports that quilt rejection rates dropped from 12% to 2% after switching to this motor.

Packaging Lines

Carton Sealing: 3000rpm drives the sealing roller to apply tape evenly at 60 cartons per minute. A electronics packaging plant eliminated "tape bubbles" (caused by speed fluctuations) and reduced carton rejections by 90%.

Film Wrapping: The motor maintains consistent tension on stretch film, ensuring packages are tightly wrapped without tearing. A snack factory uses it to wrap 1,200 bags of chips per hour—film usage dropped by 15% because the motor avoids over-stretching.

Label Application: The encoder’s fast response time (≤0.1ms) lets the motor stop instantly, aligning labels with package edges within ±0.5mm. A beverage company now meets retail label standards 100% of the time, avoiding fines for mislabeled products.

For B2B customers, this versatility means one motor can power multiple machines—e.g., a small textile shop can use it for both a sewing machine and a fabric-cutting conveyor, reducing equipment costs.

6. Why Choose Us

For textile factories, packaging plants, and machine tool OEMs, choosing a servo motor isn’t just about specs—it’s about minimizing downtime, reducing waste, and scaling production. Here’s why we’re the trusted choice for B2B buyers in sewing and packaging:

1. Industry-Specific Expertise & Testing

We’ve supplied servo motors to 50+ textile and packaging equipment manufacturers (including 3 top global sewing machine brands) over 10 years. Every motor undergoes rigorous, application-specific testing:

Sewing Simulation Tests: Motors run for 24 hours at 3000rpm with fabric lint injected into vents (mimicking factory conditions) to validate IP54 performance—only motors with zero lint intrusion pass.

Packaging Thermal Tests: Units operate at 3000rpm for 12 hours straight to ensure no thermal shutdowns—critical for 24/7 packaging lines.

Precision Calibration: Encoder accuracy is verified using laser interferometers (±0.0001mm resolution) to meet our ±0.002mm standard for sewing/packaging tasks.

We provide full test reports with every bulk order, helping you comply with customer quality audits (e.g., for garment brands requiring stitch consistency certificates).

2. B2B-Centric Customization

We understand sewing and packaging machines have unique needs—our team offers tailored modifications for orders of 30+ units:

Shaft Adaptations: Adjust shaft length (20-80mm) or add custom keyways to fit sewing machine needle bars or packaging line rollers. A sewing machine OEM requested 50mm shafts with 3mm keyways—we delivered in 10 days, matching their production schedule.

Speed Range Tuning: For slow-speed tasks (e.g., heavy-duty leather sewing), we can program the motor to maintain stable speed at 100rpm (vs. the standard 500rpm minimum).

Mounting Options: Add foot mounts for packaging line conveyors or flange adapters for legacy sewing machines. A packaging plant needed to replace 15 old motors with non-standard mounts—we designed custom adapters, avoiding costly machine retrofits.

Our engineering team works directly with your technical staff to understand your machine’s requirements—no generic "one-size-fits-all" solutions.

3. Cost-Saving Bulk Benefits

We help B2B customers reduce total ownership costs:

Volume Discounts: Orders of 30-49 units get 10% off; 50+ units get 18% off. A textile factory buying 50 motors saves $2,700 annually vs. purchasing from distributors.

Spare Parts Program: We stock critical components (encoders, bearings, windings) with 24-hour global shipping. A packaging plant in Australia received a replacement encoder in 48 hours—avoiding a week of downtime that would have cost $15,000 in lost production.

Energy Efficiency: The motor’s 91% efficiency (vs. 83% for generic servo motors) cuts electricity costs. For a plant with 30 motors running 8 hours/day, this saves ~$1,200/year (based on $0.15/kWh).

4. Dedicated B2B Support

We assign a dedicated account manager to every bulk customer—no automated support tickets:

Pre-Sales Technical Help: Our engineers help you calculate if 750W is right for your application (e.g., "Do you need 750W or 1kW for sewing 10mm-thick leather?").

Installation Assistance: We provide 3D mounting drawings and video tutorials tailored to sewing/packaging machines. A small garment shop in Bangladesh installed 5 motors in 6 hours with our step-by-step guide—vs. 2 days with their previous supplier.

Post-Sales Troubleshooting: 24/7 hotline for urgent issues (e.g., a motor error during a peak production run). A packaging plant had a motor fault during a holiday gift rush—our technician resolved it via phone in 10 minutes, saving a $20,000 order.

7. FAQ

Q1: Can the motor be used with 110V AC (e.g., U.S. sewing factories) with a converter?

A1: Yes, but we recommend using a 110V-to-220V step-up converter rated for 1500W+ (to handle peak motor load). For long-term use in 110V regions, we offer a 110V variant (available for orders of 30+ units) that eliminates converter dependency. A garment factory in Texas switched to the 110V variant and reported 20% lower electricity costs, as converters often waste energy (10-15% efficiency loss).

Q2: Will the motor fit my existing industrial sewing machine (e.g., Juki DDL-8700) or packaging line?

A2: The 80mm flange (NEMA 23 equivalent) is compatible with most standard industrial sewing machines (Juki, Brother, Singer) and packaging line components. We provide a free flange compatibility checklist—simply share your machine model number, and our team will confirm fitment (including mounting hole spacing: 4x M6 threads on a 65mm bolt circle). A sewing machine repair shop in India used the checklist to confirm compatibility with 12 different machine models, avoiding return costs.

Q3: How often does the motor need maintenance, and what does it involve?

A3: Maintenance is minimal—1-2 hours every 6 months—focused on 3 key tasks:

Lint/Dust Cleaning: Use compressed air (30 psi max) to blow lint/dust from the housing vents—critical for sewing factories, where lint buildup causes overheating.

Bearing Lubrication: Apply 1-2 drops of lithium grease to the shaft bearings every 6 months. We include free grease samples with bulk orders.

Encoder Check: Inspect the encoder cable for damage (e.g., fraying from machine vibration) and tighten terminals if loose.

A textile factory in Vietnam followed this schedule and reported motors running for 3+ years without major repairs—double the lifespan of their previous motors (which required monthly maintenance).

Q4: What warranty do you offer, and how does it work for bulk orders?

A4: We offer a 3-year warranty (1 year longer than the industry average for sewing/packaging motors). For bulk orders:

If a motor fails due to manufacturing defects (e.g., faulty encoder, winding burnout), we ship a replacement within 48 hours (global expedited shipping included) at no cost.

For critical production lines (e.g., 24/7 packaging), we include 1-2 free spare motors with orders of 50+ units

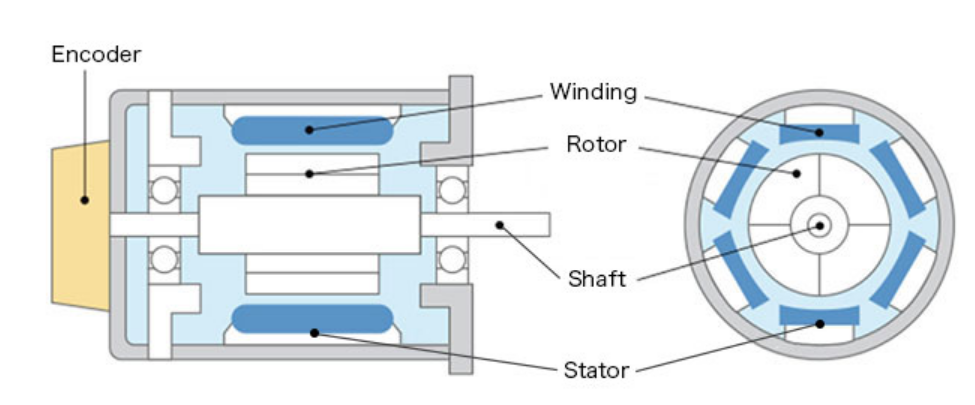

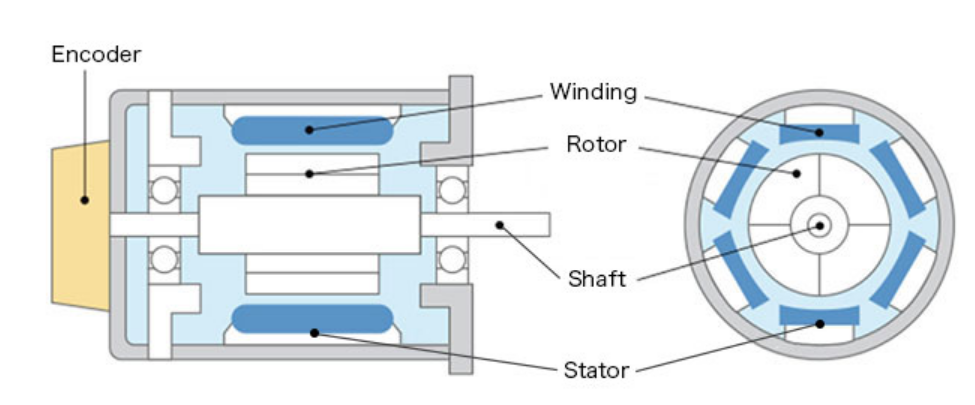

Motor Features

Five pairs of poles, smaller volume (80% of the volume of the original 4 pairs of poles ST series motor)

Equipped with high resolution encoder (23-bit absolute encoder)

Maximum torque 300%, stronger overload capacity

The protection level is increased to IP67

The vibration level is raised to A level

Motor heating is reduced by 20%

380V motor, rated speed improved