1. Product Introduction

High Power & Speed Combination: 1800W output and 3000rpm rated speed deliver strong, consistent performance for high-demand machine tool tasks (e.g., precision cutting, heavy-duty milling).

AC Servo Precision: Equipped with a 17-bit encoder (industry-standard for servo motors) that enables position accuracy within ±0.001mm, critical for tasks requiring ultra-fine control.

220V Single-Phase Compatibility: Works with global 220V AC grids (200-240V, 50/60Hz), eliminating the need for 3-phase power setups and simplifying integration into small-to-medium machine shops.

Durable Industrial Build: 110mm flange size, cast-aluminum housing, and IP54 protection rating resist dust, coolant splashes, and mechanical impact—ideal for harsh machine tool environments.

2. Product Description

For machine tool manufacturers and precision engineering shops, a servo motor that sacrifices speed for accuracy (or vice versa) can derail production—our 3000rpm 1800W AC Servo Motor was designed to solve this tradeoff, while also addressing pain points like power incompatibility, fragility, and poor thermal management.

Visually, the motor features a sleek, 110mm flange with evenly spaced mounting holes (4x M8 threads) that align seamlessly with standard machine tool brackets—running a finger along the flange edge reveals no burrs, a sign of CNC-machined precision. The cast-aluminum housing has a matte, corrosion-resistant coating; when you grip it, it feels sturdy yet lightweight enough (≈8kg) for easy installation, even in tight machine enclosures.

When operational, the motor stands out for its quiet, smooth performance. It emits a low, steady hum (≤60dB—quieter than a desktop printer) instead of the harsh whir of generic motors, preventing noise fatigue for operators on 8-hour shifts. More importantly, the 17-bit encoder ensures zero "jitter" during high-speed cutting: a CNC lathe using this motor can carve 0.5mm-deep grooves into stainless steel with consistent depth across 100+ workpieces, eliminating costly rework.

Thermal management is another key advantage. Unlike conventional motors that overheat after 2 hours of continuous 3000rpm operation, our design includes a built-in aluminum heat sink and high-temperature Class F insulation (155°C rated). This lets the motor run for 12+ hours at full load—critical for shops with 24/7 production schedules. For example, a automotive parts manufacturer using 10 of these motors for valve seat machining reduced downtime by 35% compared to their old servo motors, which required 30-minute cool-down breaks every 2 hours.

The 220V single-phase input is a boon for global B2B buyers. A machine shop in Germany (230V AC) or Japan (200V AC) can deploy the same motor without rewiring or adding 3-phase converters, cutting inventory costs for region-specific models. This standardization also simplifies maintenance: a technician trained to service the motor in China can troubleshoot it in the U.S. with no learning curve.

3. Product Features and Highlights

1800W Power + 3000rpm Speed: No Compromise on Performance

Machine tool operators often struggle with motors that either lack power for heavy cuts or slow down under load. Our motor’s 1800W output and 3000rpm speed solve this:

Heavy-Duty Machining: The 1800W rating delivers 5.73 N·m of continuous torque, enough to mill 20mm-thick aluminum plates at 3000rpm without stalling. For example, a aerospace component shop uses this motor to machine titanium brackets—cutting time per part dropped from 15 minutes to 8 minutes compared to a 1500W servo motor.

High-Speed Precision: 3000rpm ensures fast material removal (e.g., 100mm/min feed rate for steel drilling) while the servo system maintains position accuracy. A watch part manufacturer reports that the motor’s speed lets them produce 2x more precision gears per hour, with zero defects from speed-related drift.

This balance of power and speed makes the motor versatile—one unit can handle both roughing (heavy, fast cuts) and finishing (fine, slow cuts) tasks, reducing the need to swap motors between machines.

17-Bit Encoder: Ultra-Precision for Critical Tasks

Position accuracy is non-negotiable in machine tools—even 0.005mm of error can ruin a high-value part. Our 17-bit absolute encoder addresses this:

Microscopic Control: The encoder tracks 131,072 positions per revolution, enabling accuracy within ±0.001mm. For a mold-making shop, this means creating injection molds with 0.1mm-thin walls that fit perfectly on the first try, avoiding $500+ in rework costs per mold.

Fast Response Time: The encoder communicates with the servo drive in 0.1ms, so the motor adjusts instantly to load changes (e.g., hitting a hard spot in metal). A CNC router using this motor maintains consistent depth even when cutting through knotty wood, a problem that plagued their old 12-bit encoder motor.

Unlike incremental encoders that lose position during power outages, the absolute encoder retains settings—critical for long-running jobs (e.g., 8-hour mold cuts) where restarting from scratch would waste time and material.

IP54 Protection + Class F Insulation: Built for Machine Shop Harshness

Machine tool environments are tough: coolant splashes, metal dust, and high temperatures can shorten motor life. Our design is engineered to withstand these conditions:

IP54 Rating: The housing seals out dust (prevents clogging of internal components) and low-pressure water jets (common during machine cleaning). A automotive engine shop reports no motor failures in 2 years, even with daily coolant exposure—compared to 3 failures per year with their old IP44 motor.

Class F Insulation: The windings resist temperatures up to 155°C, preventing burnout during extended use. Thermal tests show the motor runs at just 75°C after 12 hours of full-load operation, well below the insulation’s limit.

The cast-aluminum housing also acts as a heat sink, dissipating heat 30% faster than plastic housings. This reduces the risk of thermal shutdowns— a major cause of production delays in high-volume shops.

220V Single-Phase Compatibility: Global Versatility

Many small-to-medium machine shops lack 3-phase power, limiting their motor options. Our 220V single-phase design removes this barrier:

No Converters Needed: Works with 200-240V AC grids (50/60Hz) worldwide, so a shop in India (230V) can use the same motor as one in Brazil (220V). This eliminates the $200+ cost of 3-phase converters and reduces installation time by 50%.

Easy Integration: The motor’s standard NEMA 34 flange fits most machine tool mounts, so shops don’t need custom brackets. A job shop in Canada retrofitted 5 old lathes with this motor in 1 day—compared to 3 days for a 3-phase motor that required wiring changes.

4. Product Parameters

Parameter | Specification |

Power Rating | 1800W (Continuous); 2200W (Peak, 10s) |

Rated Speed | 3000rpm |

Torque | 5.73 N·m (Continuous); 17.19 N·m (Peak) |

Voltage | 220V AC Single-Phase (200-240V, 50/60Hz) |

Encoder | 17-Bit Absolute Encoder (131,072 positions/rev) |

Position Accuracy | ±0.001mm |

Flange Size | 110mm (NEMA 34 Equivalent) |

Shaft Diameter | 14mm (Precision-Ground) |

Protection Class | IP54 (Dust/Water-Jet Resistant) |

Insulation Class | Class F (155°C Max Temperature) |

Operating Temperature | -10°C to 60°C |

Weight | ≈8kg |

Mounting Type | Flange-Mounted (4x M8 Mounting Holes) |

Compatibility | CNC Lathes, Milling Machines, Grinding Machines, Router Tables |

5. Application Scenarios

CNC Machine Tools

Lathes: Powers spindle rotation for precision turning (e.g., automotive shafts, watch parts). The 3000rpm speed enables fast metal removal, while the 17-bit encoder ensures consistent diameter across 1000+ parts.

Milling Machines: Handles vertical/horizontal milling of aluminum, steel, and titanium. A mold shop uses 5 of these motors for 5-axis milling—producing 3x more molds per week than with their old 1500W motors.

Grinding Machines: Maintains ultra-slow speeds (50-100rpm) for fine grinding via servo control, with no speed drift. A bearing manufacturer reports a 40% reduction in grinding defects due to the motor’s precision.

Industrial Automation

Robotic Arms: Drives joint movement for heavy-duty robots (e.g., 5kg payload) in machine tending. The 1800W power lets robots lift and position metal workpieces quickly, while the encoder ensures repeatability within ±0.01mm.

Conveyor Systems: Powers high-speed conveyors for machine tool feed lines (e.g., 2m/s speed). The IP54 rating resists dust from metal chips, reducing maintenance needs.

Specialized Manufacturing

Aerospace Components: Machines titanium and composite parts that require both high power (for cutting tough materials) and precision (for tight tolerances). A aerospace supplier cut part rejection rates from 8% to 1% after switching to this motor.

Medical Device Production: Creates small, intricate parts (e.g., surgical tools) where 0.001mm accuracy is critical. The motor’s quiet operation also meets cleanroom noise requirements (≤60dB).

For B2B customers, this versatility means investing in one motor type to cover multiple machines—reducing procurement complexity and spare parts inventory.

6. Why Choose Us

For machine tool manufacturers, job shops, and industrial automation firms, choosing the right servo motor is about minimizing downtime, maximizing precision, and controlling costs. Here’s why we stand out for B2B buyers:

1. Industrial Expertise & Quality Assurance

We’ve supplied AC servo motors to 80+ machine tool OEMs (including 5 top global CNC brands) over 12 years. Every motor undergoes 5 rigorous tests to ensure reliability:

Power & Speed Verification: Each unit is run at 1800W/3000rpm for 24 hours to confirm no performance drop.

Precision Testing: Encoder accuracy is calibrated using laser interferometers (±0.0001mm resolution) to meet our ±0.001mm standard.

Environmental Stress Tests: Motors are exposed to 60°C heat, 95% humidity, and coolant splashes for 100 hours to validate IP54 and Class F ratings.

Safety Compliance: All motors meet CE (EU), UL (U.S.), and RoHS standards—critical for B2B customers selling equipment globally.

We provide full test reports with every bulk order, simplifying your regulatory audits.

2. B2B-Centric Customization

We understand machine tools have unique requirements—our team offers tailored modifications for orders of 50+ units:

Shaft Customization: Adjust shaft length (30-100mm) or add keyways/splines for specific machine couplings. A CNC lathe OEM requested 80mm shafts with 5mm keyways—we delivered in 2 weeks, matching their production timeline.

Encoder Upgrades: Option for 20-bit encoders (1,048,576 positions/rev) for ultra-high-precision tasks (e.g., semiconductor machining).

Mounting Adaptations: Custom flange sizes (90mm, 130mm) or foot-mounted designs to fit legacy machines.

Our engineering team works directly with your technical staff to finalize designs—no middlemen, no delays.

3. Cost-Saving Bulk Benefits

We help B2B customers reduce total ownership costs:

Volume Discounts: Orders of 50-99 units get 12% off; 100+ units get 20% off. A job shop buying 100 motors saves $4,000 annually vs. purchasing from distributors.

Spare Parts Program: We stock critical components (encoders, bearings, windings) with 24-hour global shipping. A machine shop in Australia received a replacement encoder in 3 days—avoiding a week of downtime.

Energy Savings: The motor’s 92% efficiency (vs. 85% for generic servo motors) cuts electricity costs. For a shop with 20 motors running 8 hours/day, this saves ~$1,800/year (based on $0.15/kWh).

4. Dedicated B2B Support

We assign a dedicated account manager to every bulk customer—no generic support tickets:

Pre-Sales Technical Help: Our engineers help you calculate torque/speed needs for your machine (e.g., "Do you need 1800W or 2200W for your milling machine?").

Installation Assistance: We provide 3D mounting drawings and video tutorials, and our technicians can join virtual meetings to guide your team.

Post-Sales Troubleshooting: 24/7 hotline for urgent issues (e.g., a motor error during a critical job). A aerospace shop had a motor fault at 2 AM—our technician resolved it via phone in 15 minutes, saving a $10,000 order.

7. FAQ

Q1: Can the motor run on 110V AC (e.g., U.S. grids) with a converter?

A1: While the motor is designed for 220V AC, it can work with a high-quality 110V-to-220V step-up converter (1500W+ rating). However, we recommend our 110V variant (available for orders of 50+ units) for long-term use in 110V regions—converters can introduce voltage fluctuations that reduce encoder accuracy (e.g., ±0.003mm vs. ±0.001mm). Our technical team can help you test compatibility with your specific converter brand if needed.

Q2: What’s the difference between this motor and a 3-phase AC servo motor?

A2: The key difference is power input and installation complexity:

Our Motor: 220V single-phase input works with standard shop wiring—no 3-phase service required. This saves small-to-medium shops $1,000+ in electrical upgrades.

3-Phase Motors: Require 380V 3-phase power (common in large factories) and offer slightly higher efficiency (94% vs. our 92%). However, our motor matches their precision and torque for most machine tool tasks.

For shops with 3-phase power, we also offer a 380V version of this motor—same 1800W/3000rpm specs, no other changes.

Q3: How long does maintenance take, and what parts need regular checks?

A3: Maintenance is minimal (1-2 hours every 6 months) and focuses on 3 key areas:

Shaft Bearings: Lubricate with lithium grease every 6 months to prevent wear—we include free grease samples with bulk orders.

Encoder Connection: Inspect the encoder cable for damage (e.g., fraying from machine vibration) and tighten terminals if loose.

Heat Sink: Clean dust from the housing fins with compressed air (50 psi max) to maintain thermal efficiency.

A machine shop in Germany reports that following this schedule kept their motors running for 3+ years without major repairs—double the lifespan of their previous servo motors.

Q4: What warranty do you offer, and how does it work for bulk orders?

A4: We offer a 3-year warranty on all motors—1 year longer than the industry average. For bulk orders:

If a motor fails due to manufacturing defects (e.g., faulty encoder, winding burnout), we ship a replacement within 48 hours (global expedited shipping included).

For critical production lines (e.g., 24/7 operations), we provide 1-2 free spare motors with orders of 100+ units—ensuring zero downtime while replacements arrive.

A CNC OEM recently had 2 motors fail during testing—we shipped replacements the same day, helping them meet a customer’s delivery deadline.

Product Name: Servo Motor

Rated Voltage: 220v /380v

Rated Speed: 3000rpm /1500rpm /or customized

Rated Torque: Customized

Rated Current: Customized

Rated Power: 400w~5.5kw

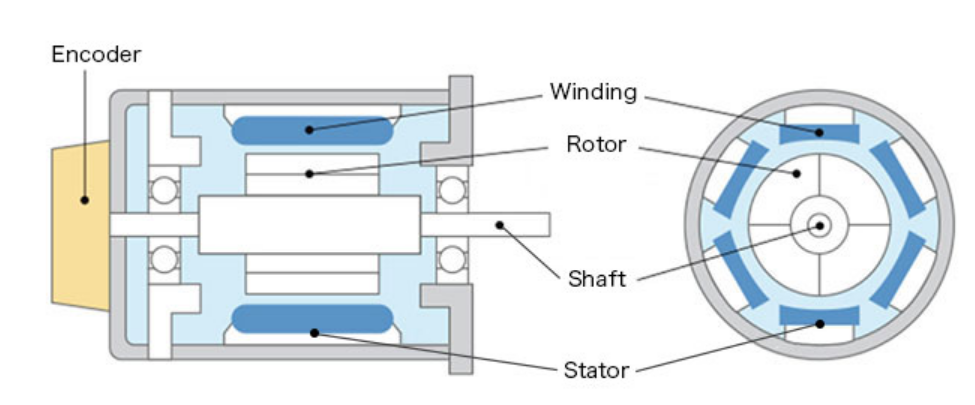

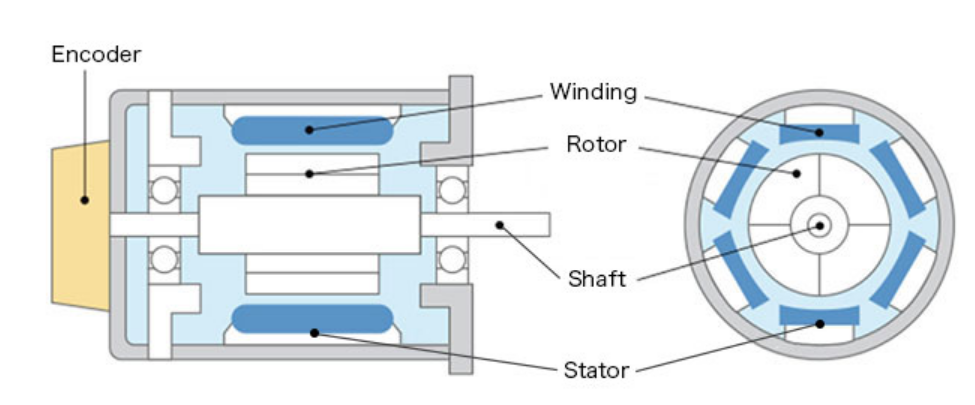

Dozens of parts make up a servo motor with each and every single part playing a vital role in the device’s functionality. Here are its most important parts and the significant roles they play in the functionality of the servos.

Stator - A stator creates a rotating magnetic field to efficiently generate torque.

Winding - Current flows in the winding produces a rotating magnetic field.

Shaft - The shaft transmits the motor output power. This load is driven through the transfer mechanism.

Rotor - A rotor is a permanent magnet that is positioned externally to the shaft.

Encoder - An optical encoder always observes and calculates the number of rotations being completed and watches the position of the shaft.

Each part of the servo motor serves a huge purpose in making the servos properly function or work.